New Colorado Seminar Center takes education to next level for manufacturer’s customers

Viega gets hands-on.

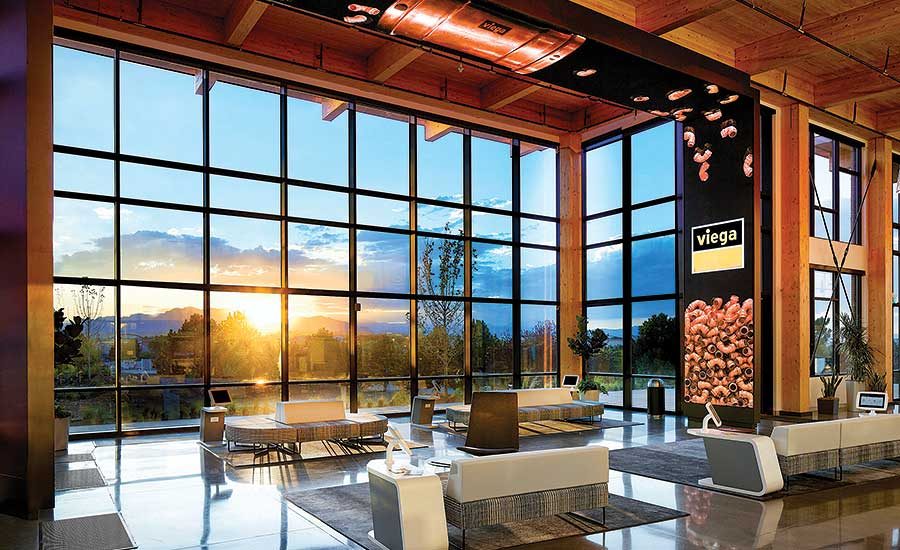

Viega’s state-of-the-art Colorado Seminar Center already is on track to host more than 2,100 students this year. The center opened in April. Photos courtesy of Viega

One key feature of the Colorado Seminar Center is its expansive Interactive Learning Center hallway that allows attendees to see, touch and experience Viega products while learning about their many capabilities. Photos courtesy of Viega

Viega’s McPherson, Kansas manufacturing campus continues to enjoy explosive growth. A new 205,000-square-foot manufacturing plant was completed in June. Photos courtesy of Viega

Viega wowed the PHCP-PVF industry in 2006 with the opening of its New Hampshire Seminar Center in Nashua.

Some 13 years later, the wow has been turned up even more with the opening of the Viega Colorado Seminar Center in Broomfield, Colorado. The training center sits next to the manufacturer’s new headquarters building and is billed by the company as an investment in trade education and empowerment.

The Colorado Seminar Center opened in April and a grand-opening event was held in August that welcomed contractors, distributors, reps and invited guests.

The state-of-the-art building with the mountains in the background includes four classrooms, two workshops and an expansive Interactive Learning Center hallway that allows attendees to see, touch and experience Viega products while learning about their many capabilities, the company pointed out.

“With New Hampshire we had a really good vision of what we wanted to do there,” Viega Marketing Coordinator Jim De Broeck told PM during the Colorado grand opening. “We wanted to step it up to a new level with Broomfield and we have been able to do that. To borrow a gentleman’s comment, we went from New Hampshire 1.0 to version 3.0 in Broomfield. It’s an eye-catcher with the gateways in the front of the building and the interactive displays. We have new and exciting content. All the technology here is upgraded.”

The 23,000-square-foot building features Viega products and technology throughout. Exposed ceilings provide a clear view of the fire sprinkler system and its MegaPress fittings. Copper lines with ProPress fittings provide water supply, and water flows from the manifolds through carbon steel lines with MegaPress fittings. Radiant heating and cooling keeps the building comfortable, while snow-melt systems keep sidewalks free of ice and snow during winter. The restrooms feature wall-hung bowls, Viega in-wall carriers and Visign flush plates.

“What we want to convey to our customers is how innovative our products are and how they are going to make their lives easier,” De Broeck said. “They are going to save them time and money. We want them to be successful and our products can help them be successful.

“We didn’t want to just have educational classes. We wanted our customers to interact with the products — physically touch them and learn from them. We want to give them a sense of feel. That’s what learning is all about. We are bringing our products to life. And each of those displays tells a different story about how Viega can help you solve problems.

Single- and multi-day (up to 5 days) classes are offered, ranging from radiant system design and fire protection to hydronics and pathogen prevention.

Viega Manger of Technical Training Bo DeAngelo noted the Colorado center is on track to already host more than 2,100 students in less than a year since its opening, and to date more than 40,000 people have taken courses at the centers. The manufacturer noted courses are subsidized by Viega to keep them affordable for all its customers.

“The best technology is useless without tradespeople to implement it, and any job is only as good as the work behind it,” Viega CEO Dave Garlow said. “Viega appreciates the skill and hard work of its customers and all tradespeople, and is proud to provide them with education and training.”

Viega also elaborated on its Viega Trades Education Network or VTEN, which partners with trade schools and community colleges to supplement their curriculum on plumbing and hydronic systems — helping the next generation of tradespeople.

VTEN provides its 95 partner UAs and schools with tooling packages, access to LoopCAD radiant heating and cooling systems design software and Viega’s eLearning platform. Viega also offers instructors’ conferences, workshops and curriculum modules that integrate with each school’s program. VTEN also offers credentialed classes for Viega products.

McPherson motors on

A day earlier, invited guests toured Viega’s massive manufacturing complex in the Wichita, Kansas suburb of McPherson.

While Viega moved its headquarters to Broomfield in 2016, it continues to expand and invest in McPherson.

This summer the manufacturer completed a two-year building program in McPherson that includes a 90,000-square-foot expansion of a manufacturing plant (that was completed in December 2017), a new 205,000-square-foot manufacturing plant (completed in June) and a new 25,000-square-foot tool shop and apprentice building (completed in July). Currently, a 55,000-square-foot logistics expansion is in the works.

“We’re growing like crazy,” Viega Director of Manufacturing Eric Wicker said during the tour. “There have been a lot of changes and we’ve had to hire a lot of people and get them up to speed.”

The McPherson complex is where the company produces its PureFlow line of PEX product, as well as select fittings from the ProPress Copper and MegaPress product lines.

McPherson also is home to Viega’s master distribution center for North America. The center incorporates the latest technology and automation, as well as an upgraded warehouse management system that provides faster product turnaround, the company explained. With additional metals products being manufactured in McPherson, a larger distribution center for both metals and PEX products was needed, it added.

Viega has more than 700,000 square feet of manufacturing and warehouse space on the 127-acre campus in McPherson. It employs 300 people there and expects to add more.

“Viega is an extremely efficient organization,” Senior Process Engineer Tom Brunholtz said. “With this expansion it’s run, hit the concrete and we are making products.”

Wicker explained Viega partners with a local Kansas community college on an apprentice program. In three years the program has trained 18 individuals and five more apprentices were brought aboard this year. “We completely pay for their college program,” he said. “They can work 25-40 hours here and get that hands-on experience and training. When they come out of the program, we guarantee them a job.”

Back to Colorado, Viega’s new headquarters building in Broomfield spans 55,000 square feet and is built of cross-laminated timber beams imported from Austria. Exposed ceilings give employees and visitors a clear view of the many uses of Viega’s technology, the company pointed out. The headquarters officially opened in January, and houses more than 150 employees with ample room for more.

“It’s so exciting to see the growth we’ve had from the late 1990s to where we are now,” De Broeck said. “It’s exciting to be part of something that is growing and having an impact on the market.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!