The safest way to prevent hot water scalding

Scald protection should be planned and implemented properly in residential and commercial settings.

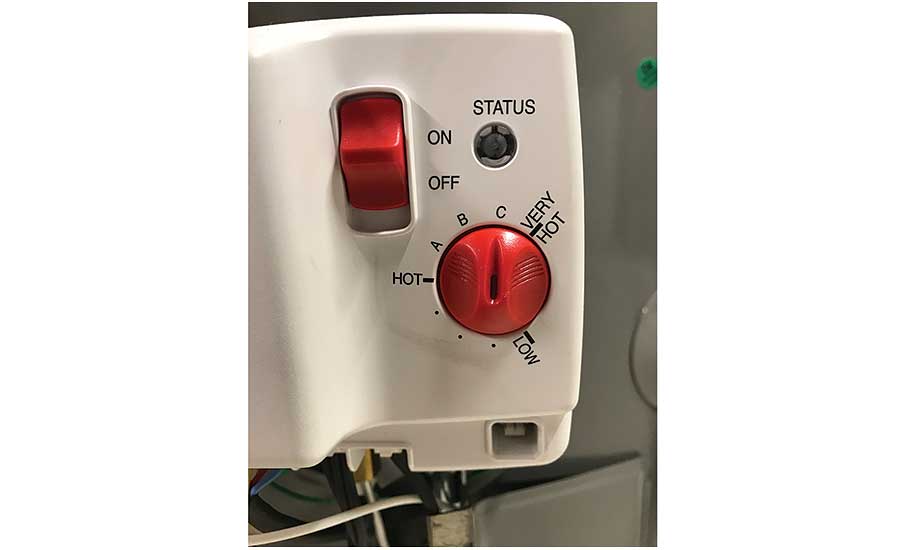

Most thermostat adjustment scales are relative and vague.

Preventing scalding is indeed something that requires serious consideration. Especially in these highly unnerving times, it may be comforting to know that it is one dangerous foe that can be easily vanquished with the right technical know-how and equipment.

Hot water scalding is one of the leading causes of serious burns. In the United States, scald injuries from tap water send about 112,000 people to the emergency room each year — hospitalizing nearly 7,000. Small children, the elderly and persons with disabilities are at a higher risk if they are impaired from quickly getting away from dangerously hot water.

Scalding is a second-degree burn to the skin caused by hot water or steam. Deep damage and blistering can be very severe depending on the length of exposure time to the high temperature moisture. Scald burns can even be fatal if a large area of the body is burned.

Many residential scalding incidents are caused by water heaters that are set at temperatures above 120°. It can be difficult for a homeowner to accurately determine the optimal temperature setting on their water heater. Most thermostat adjustment scales are relative and vague, as shown in Figure 1. Combine that with the fact that most water heaters have basic on/off thermostatic control that can vary by more than +/-10° and, consequently, the water temperature that is actually delivered at the point-of-use can range from warm to hazardously hot.

One way to know if the temperature is safe is to measure the temperature of the hot water coming out of each hot fixture or point-of-use, with a thermometer. Iterative point-of-use temperature measuring and heater setting adjustment should be done until all fixtures deliver water at or below 120°.

The safest and most accurate way to control hot water supply “point-of-distribution” temperature is by installing an ASSE 1017 “Performance Requirements for Temperature Actuated Mixing Valves for Hot Water Distribution Systems” compliant mixing valve at the water heater. A mixing valve is adjustable to a specific temperature and can be set at 120°, which will assure no fixture will deliver unsafe hot water.

The valve mixes the hot water from the heater with cold fresh water to provide accurately tempered water, which then serves the hot pipes leading to the home faucets and fixtures. Some states, such as Vermont, require mixing valves on all point-of-distribution water heaters, others do not.

An important note about ASSE 1017 point-of-distribution mixing valves; they should not be considered scald protection valves because they can be adjusted to temperatures greater than 120°. There are some dual-rated ASSE 1017 and 1070 mixing valves on the market that feature a mechanical means of limiting the adjustment to 120° maximum when the valve is used at the point-of-use.

In most buildings, 120° tap water is considered a maximum safe temperature. It takes about five minutes of exposure to 120° water to cause burns. Higher temperatures are dangerous; a 30-second exposure to 130° water, and a 6-second exposure to 140° water will cause burns.

Figure 2 illustrates the Temperature —Exposure time risk for hot water scalding.

Temperature — Exposure time conditions hold true for all hot water systems, but the approach to scald protection in commercial applications is different than from residential. One reason is the larger volumes of stored and distributed hot water in the commercial premise piping is not replenished with fresh clean water as often as the water in a typical residence. This water can become “old” and stagnant, which promotes the growth of bacteria such as Legionella. As a result, commercial building water is typically controlled to elevated temperatures, for example 140°, to control and kill Legionella. With elevated temperatures in the distribution and recirculating piping, scald protection at every point-of-use fixture is absolutely critical.

Another reason to make and/or store hot water at elevated temperatures is for commercial dishwasher and laundry facility use. The extra-hot water produced by the heater(s) can be used directly for dish washing and laundry, and a mixing valve can be used to reduce and control the temperature for domestic hot water for the secondary distribution system and recirculation piping.

Many designers, consultants and water experts agree that producing or storing commercial domestic hot water around 150° to 160° and distributing/recirculating at 130° to 140° is good practice to reduce the potential for dangerous bacteria growth.

This approach is safe as long as the system is designed and built for elevated temperatures and includes scald protection devices at all points-of-use. These devices are typically thermostatic mixing valves that are designed, tested and in compliance with standards such as ASSE 1070 “Performance Requirements for Water Temperature Limiting Devices” or ASSE 1016 “Automatic Compensating Valves for Individual Showers and Tub-Shower Combinations.”

Shower and Tub-Shower valves with integral scald-protection technology are commonly built-in to the fixture. Where the fixture itself does not have built-in scald protection, it is necessary to install an ASSE 1070 compliant scald-protection valve in the supply pipes to the fixture. These valves are available in 3-way or 4-way body patterns. Schematic examples of both are shown.

A 3-way scald protection valve (Figure 3a) has one inlet for hot, one inlet for cold, and one mixed outlet for the tempered water that is piped to the hot tap of the fixture. When the fixture is a 2-pipe type, meaning it has a hot and a cold tap, a tee is required on the cold inlet side of a 3-way valve. The tee diverts the cold supply to the valve cold inlet and to the cold tap of the fixture. Some fixtures are 1-pipe, meaning there is only one connection for tempered water. Examples are motion-activated fixtures such as those located in common areas and public lavatories.

A 4-way scald protection valve (Figure 3b) also has one inlet for hot, one inlet for cold and a mixed outlet for the tempered water that is piped to the hot tap of the fixture. The fourth port connects to the cold tap of the fixture and is part of the valve body, which eliminates the need for the extra cold inlet tee. When a 4-port valve is used on a 1-pipe fixture, a cap (or plug) is used to block the cold outlet port of the valve (Figure 3c).

All ASSE 1070 compliant valves are required to have a maximum set point adjustment of 120° and required to have check valves (or other means of preventing cross flow) on both inlet ports to protect against potential cross flow of hot/cold water. These valves also must provide fast shutdown of the incoming hot water, if the cold water supply should fail or lose pressure for some reason, to assure the discharge water does not exceed 120°.

In addition to scald protection devices that comply with ASSE 1016 and 1070, there are products that attach directly to a shower head or faucet and if/when the entering water temperature is higher than 120° the device quickly closes down. These devices comply with ASSE 1062 “Performance Requirements for Temperature Actuated Flow Reduction (TAFR) Valves for Individual Supply Fittings.”

ASSE 1069 “Performance Requirements for Automatic Temperature Control Mixing Valves” specifically applies to 1-pipe gang showers, sitz baths, spas and gang lavatories, which do not have temperature adjustments at the point of use.

ASSE 1071 “Performance Requirements for Temperature Activated Mixing Valves for Plumbed Emergency Equipment” specifically applies to 1-pipe eye washes, eye/face washes, drench showers and combination units, which also do not have temperature adjustments at the point of use.

As an industry, we have learned a lot in recent years about the dangers associated with Legionella bacteria in commercial building hot water systems, and we know that maintaining elevated temperatures in these water systems will control and kill that bacterium. We can rest assured that as long as everyone from the design engineer to the balancing contractor makes sure appropriate scald protection is planned and implemented properly, then getting scalded by tap water is no longer cause for concern.

Scald statistics can be found at www.healthcentral.com/encyclopedia/hot-water-scalding.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!