Radiant Comfort Report | May 2020

Radiant heating system solves comfort problems twice over

Residential installation leads to another hydronic project for same customer.

The main level of the home consists of seven zones with REHAU PEXa tubing stapled to the top of the subfloor with 1 1/2-inch of gypsum poured over the top of the tubing.

Because the mechanical room location was in the middle of the house, we were able to keep all our REHAU PRO-BALANCE manifolds with flow indicators in the mechanical room.

The Belanus residence was started in 2013. Our company, Arndt & Son Plumbing, began our work in June 2013, and completed the project in December 2014. We completed the plumbing, water well system and in-floor radiant heating system for the residence.

The ranch home, located in Wisconsin, features a walkout basement and exposure on all three sides of the home. The first floor and lower level of the home are 3,000 square feet each. There is a two-car garage on the upper level, and a 513-square-foot garage on the lower level. There are 13 radiant in-floor heating zones throughout the entire home, and one future zone for the east side of the lower basement garage.

The main level consists of seven zones with REHAU PEXa tubing stapled to the top of the subfloor with 1 1/2-inch of gypsum poured over the top of the tubing. All floor coverings on the first floor are tile. The two-car garage on the first floor has Spancrete on the floor with a trench drain in the garage. We installed 8-foot by 15-foot No. 10 flat-wire mesh on top of the Spancrete floor, and then poured cement over the tubing. We did not install Styrofoam insulation on the garage floor because of the 513-square-foot garage below the first floor garage. The heat transfer can go through the Spancrete to the lower garage.

The lower level of the home has seven heating zones. Here, we installed a 2-inch Styrofoam insulation with a vapor barrier and 8-foot by 15-foot No. 10 flat-wire mesh. We tied our 1/2-inch REHAU PEXa tubing with an O2 barrier to the wire mesh.

Because the mechanical room location was in the middle of the house, we were able to keep all our REHAU PRO-BALANCE manifolds with flow indicators in the mechanical room. When we installed the tubing on the first floor, we drilled down through the floor in the zoned room and ran the tails through the floor joist into the mechanical room to the manifolds.

We also installed 5/8-inch by 1/2-inch ArmaFlex insulation on the tubing in the joist space for the supply and return lines from the manifolds. The lower level tails were very close to the mechanical room manifolds, so this worked out very well. All living areas in the lower level have acid stain on the concrete floors for a finish, making this a very good low temperature radiant system. The first floor joist space was insulated below the tubing to keep the heat from coming down into the joist space, so all the heat stays in each zone only.

The boiler system was designed for future addition of a wood boiler and a geothermal system. We installed REHAU RAUGEO PEXa pipe for the geothermal system from the mechanical room to the future geothermal field outside. We also installed REHAU INSULPEX from the mechanical room to the future site for a wood boiler outside. The heart of the system is a Viessman 200W 19,000 to 125,000 Btu boiler.

The brains running the system consist of a tekmar 402 tN2 house control, two 553 heat control tN2 thermostats, twelve 528 tN2 heat-only thermostats, three tekmar 313 tN2 and one 316 tN4 wire center. We have one tekmar 553 main thermostat control on each floor in the main living areas. The other zones utilize tekmar 528 thermostats. All thermostats have a slab sensor and air sensor to control the heating and cooling system. We also used three Caleffi 2-way Thermo-Electric Zone Valves with TwisTop. On our REHAU PRO-BALANCE manifolds, we used REHAU 4-wire manifold valve actuators to control our zoning.

The Tekmar 402 tN2 house control with the tN2 stats provides some unique features. It waits until multiple zones need heat before bringing on the boiler and it continues to look for zones to bring on as it drops others off — all to keep the boiler cycling to a minimum. The other feature is that each thermostat only communicates with the wiring centers via 2-wire connection. This reduces field wiring and the number of connections at each thermostat. All of the traditional connections for heat, cooling, fan etc., are made at the wiring center, which is in the mechanical room near the equipment it controls.

The 402 house control modulates the boiler and adjusts the 3-way mixing valve to maintain variable water temperature that is reset based on outdoor temperature for radiant zones. If there is no DHW or forced air call, then the control will drive the valve wide open and maintain the correct water temperature by modulating the boiler. This feature is critical to realize the boiler’s highest efficiency.

After the first year of use, the homeowners opted out on connecting the wood boiler and geothermal system because they were blown away at the efficiencies of their current system.

SHOP WORK

Five years after we completed the radiant heating, plumbing and the water well system for the Belanus residence, we met at their 7,500-square-foot shop to redo the heating system.

The shop had an old, homemade wood boiler system where you would put the wood in the fire box outside of the building and the super-insulated 1,500-gallon water storage tank was outside the building. The owner did all of the original work on his shop when it was built years ago. This was a system that worked well over time, but it was finally time to bring it up to date.

The old system went through a lot of wood, so we looked at some of the high-efficiency wood boilers on the market. He chose the Central Boiler Classic Edge Titanium HD Series 750 with a reaction chamber. This unit burns 50% less wood, and requires less maintenance while featuring a longer and cleaner burn time. I was very impressed by this unit and its piping install, which is conveniently located in order to connect tubing.

The owner removed the old wood boiler system and built us a new mechanical room to house our new in-floor radiant heating system. The wood boiler is mounted outside the shop, away from the building to meet building codes. We installed REHAU INSULPEX from the mechanical room to the wood boiler outside. This wood boiler has Cryo-Tek-100 antifreeze for hydronic heating, so the wood boiler can be turned off without it freezing. All pumps and controls for the heating system are installed inside the mechanical room.

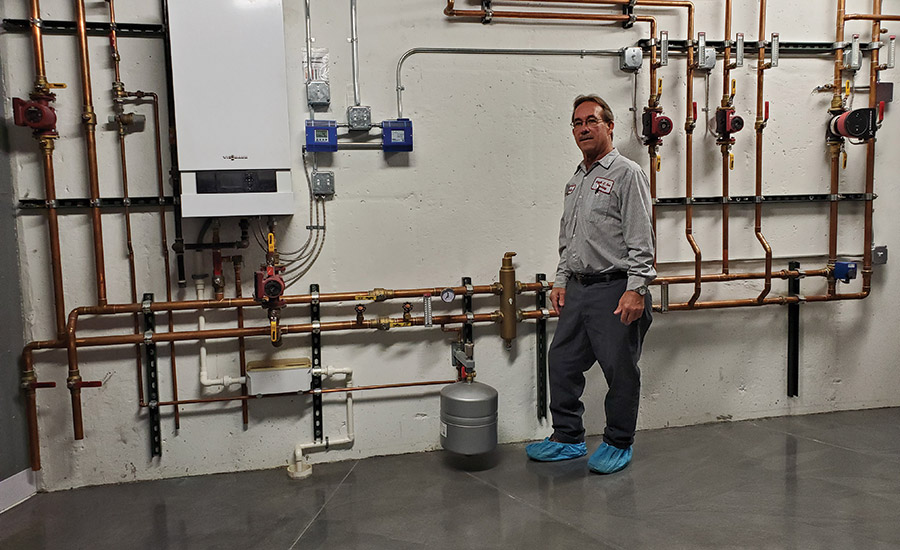

In the mechanical room, we installed a Viessmann 200W 19-125 MBtu boiler. We piped brazed-plate heat exchanger before our Viessmann boilers and installed four Grundfos 15-58 FC 3-speed circulating pumps for the heat exchanger, boiler pump and one for the 30-gallon Heat-flo indirect water heater.

For all five zones of the existing radiant heating system, we installed a Caleffi High Flow 3-way mixing valve with temperature gauge and a Grundfos ALPHA2 26-99 pump after the mixing valve to service the radiant zones.

For this system, we used tekmar 519 thermostats with slab sensors. We used a Caleffi 4-in-1 Air Dirt Hydro and Magnetic separator on our piping system. We installed an Axium glycol single-system feeder for the heating system, since it has antifreeze on the radiant heating side of the heat exchanger. With our pipping and the controls, the Viessmann boiler will only run if the wood boiler outside is not producing any heat to heat the shop.

The Viessmann boiler is controlled by a tekmar wireless outdoor sensor. The wood boiler pump runs all the time with an aquastat on the supply line to the heat exchanger. Once the aquastat reaches the set temperature, it closes the circuit to a Taco switching relay in turn, blocking the heat signal to the boiler, turning on the boiler system pump to the heat exchanger and turning off the boiler pump to the boiler.

Our motto is quality work isn’t expensive — it’s pricless. Everything we do goes to show our systems will stand the test of time.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!