Circulator pumps bring energy efficiency and cost savings to Seattle home

New pumps eliminate harmonic noise travelling from the mechanical room to the main house.

Built more than 30 years ago on the western shores of Puget Sound, a 15,000 square foot custom-built home sits picturesquely at the tip of a cove. The original homeowners who designed it still live there and take impeccable care of the residence. Three years ago, the couple discovered the home had a significant problem: A failing heating system.

The stunning home requires full-time mechanical care. Its heating system relied on outdated technology and featured inconsistencies which resulted in issues that caused mechanical failure. The couple took the challenge of designing a replacement system to Vaughn Mechanical of Tumwater, Washington.

“We found the existing heating system was antiquated and inefficient,” says Vaughn Murphy, president of Vaughn Mechanical. “The most common complaint from the owners was the harmonic noise coming from the mechanical room, which was located inside the garage attached to the home.”

The original system required some manual control, featuring circulators in an on/off configuration. The goal was to design a system that offered reliability, efficiency and simple integrated programming control. To achieve this, Vaughn designed a hydronic radiant heating system and contacted Grundfos pump dealer, Brett O’Connor of Pac West Sales to provide the circulator pumps.

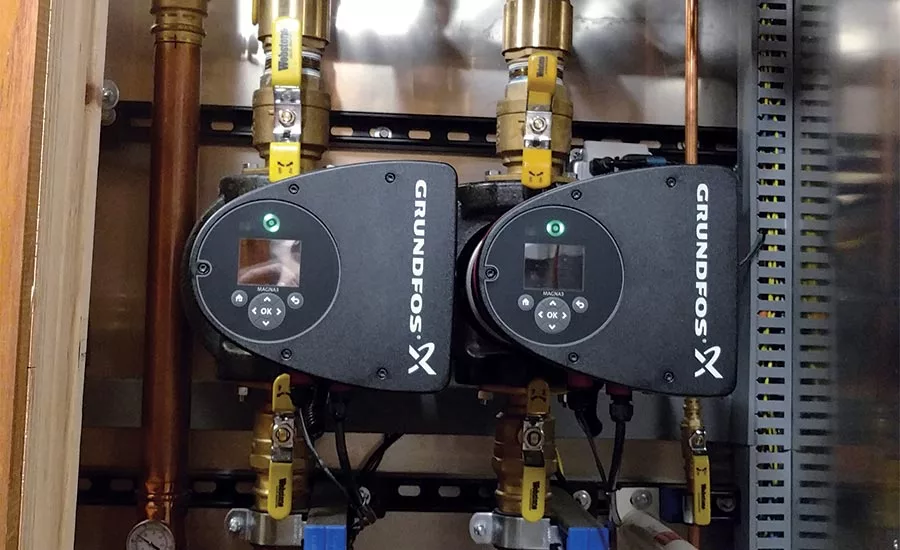

O’Connor recommended utilizing high-quality Grundfos MAGNA circulator pumps. MAGNA pumps are known for delivering low noise levels and low energy consumption — all MAGNA pumps are energy class “A.”

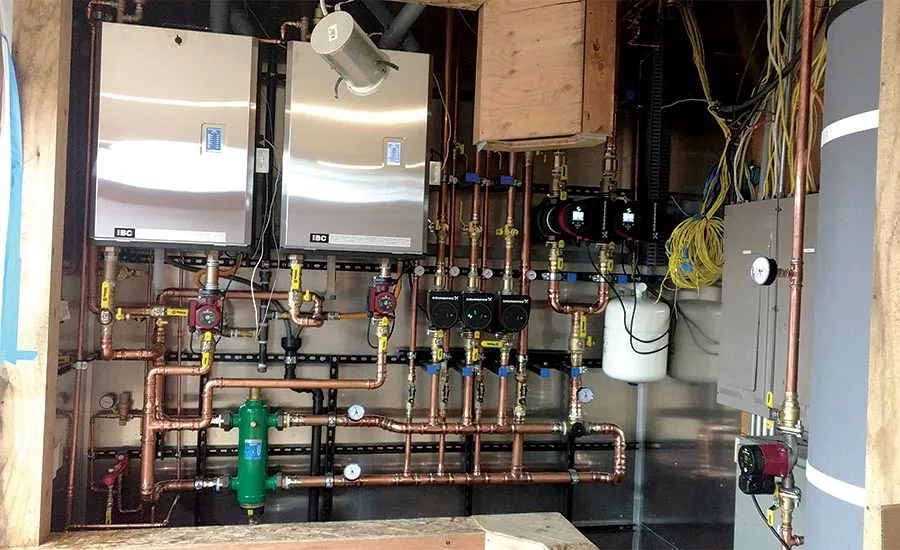

The mechanical installation features a high-performance heating system with both radiant and fan coil zones. A condensing high-efficiency IBC SL 399 Btu boiler with a Caleffi low loss header system serves the radiant heating zones. Two Grundfos high-efficiency ECM MAGNA3 40-120 circulators utilizing a lead lag control system satisfy the radiant circulation demand. Three smaller MAGNA1 32-60 pumps serve the fan coil loops within the residence. Grundfos UPS circulators are utilized as boiler pumps, and also serve the domestic hot water load.

“One of the major benefits of utilizing Grundfos MAGNA pumps is the ease of control programming to optimize efficient operation of the circulators,” O’Connor says. “This feature substantially reduced project costs and provided a simple, efficient solution.”

By designing around the Grundfos platform, the team was able to provide a high efficiency delivery system to the home while using the pumps to eliminate the harmonic noise which traveled from the mechanical room to the main house. The new design included a downsized control platform, owing to the fact it no longer needed to control the circulators in an on/off configuration. Instead, the system allowed for the individual zones to call and the circulators to operate as they were designed.

“The homeowners were very involved and paid attention to detail, so we needed to ensure we were closely aligned with the mechanical contractor, and the equipment package we specified and designed would perform as discussed,” O’Connor explains.

The full demolition, tear down and rebuild/installation took only five days to complete. When it came time to lead lag the circulators, O’Connor explained to the control contractor that it would be done by Bluetooth. In less than four minutes, all the Magna pumps were paired and running. The control contractor laughed and said he would take that process out of the work order.

Likewise, when Murphy asked when they would be ready to fire up the Grundfos pumps, O’Connor responded that the system had been running for quite some time. Later, when the homeowner asked the same question, the contractor explained the system had been up and running quietly.

The thermostat is the one touch point for the homeowners, and the system adjusts automatically in real time to temperature changes in the building. The touch panel interfaces with the system to control temperatures throughout the residence. The consistent comfort of the residence is a sign that the system is optimized and working properly.

“The new system provides no controllability of heating in the house,” Murphy says. “Instead the MAGNA system technology automates the open and close of thermal valves without manual intervention.”

After two years of operation, the system has delivered defined data to demonstrate the energy savings and increased performance of the system. The data suggests that MAGNA ECM pumps’ estimated energy reduction versus standard induction wet rotors is 60%. In addition, the MAGNA3 system analytics provide the mechanical contractor with data to optimize the radiant circulator performance.

Both Vaughn Mechanical and the homeowners were highly pleased with the outcome of the system upgrade. Based on the project’s success and the demonstrated energy and cost savings, the homeowners referred Vaughn Mechanical to another family in need of a system upgrade.

“Grundfos pumps always have been known as the silent, reliable circulators,” O'Connor says. “This project really demonstrated that Grundfos pumps are the quietest, most efficient and fully integrated circulators on the market.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!