The Glitch & The Fix: Share, and share alike

The Glitch:

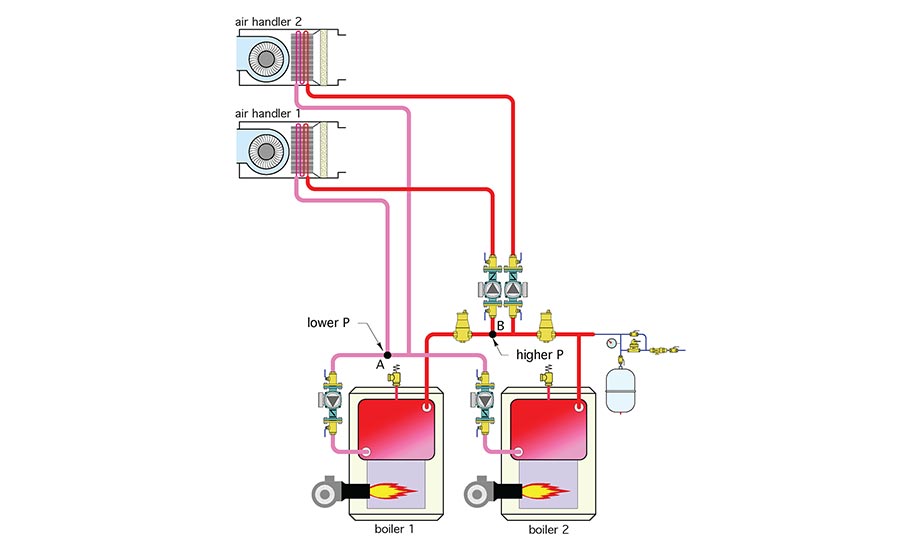

An installer is asked to pipe up two larger commercial air handlers supplied by a dual boiler setup. He’s asked to make it possible to supply either air handler from either boiler. The layout he comes up with is shown in Figure 1. The installer also places two air separators to intercept bubbles coming from either boiler.

Can you spot some shortcomings of this layout, and suggest a better way to accomplish the same objectives?

The Fix:

Consider a situation where boiler 1 is firing to send heat to air handler 1. The circulator on boiler 1 is going to create a pressure differential between points A and B. Point A will be the lower pressure, and point B will be at a higher pressure. If this pressure differential is more than about 0.5 psi, it will force flow through the spring check valve in the circulator for air handler 2, and thus create some flow through air handler 2. This is not desirable. A similar argument holds when boiler 2 is supplying air handler 2, while air handler 1 is supposed to be off.

If you look carefully, you will also see the coils in the air handlers are not piped for counterflow heat exchange. Since the air passing through the coil is increasing temperature right to left, the water flowing through the coil should be going in the opposite direction, left to right. This increases the average temperature difference between the air and water, and thus increases the rate of heat transfer.

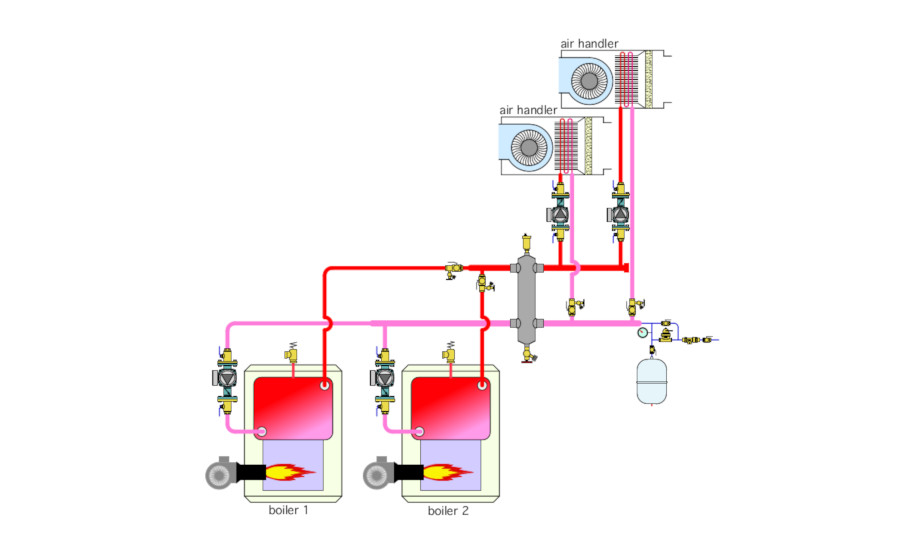

Instead of having the circulators interfere with each other, or spending money on two air separators, pipe the system as shown in Figure 2.

Each boiler connects to generously sized headers that lead to a hydraulic separator. This device also provides central air and dirt separation for the system. Another set of short and generously sized headers connects to the two zone circulators supplying the air handlers. Either air handler can be supplied from either boiler, or from both boilers firing simultaneously if needed. Each boiler can be fully isolated if necessary for service, without affecting operation of the other boiler. The combination of short, generously sized headers and the hydraulic separator prevent interference between the circulators and eliminates “ghost flow” through zones that are supposed to be off.

Download The Glitch and Fix: November 2020 in pdf form.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!