Smart + Connected Backflow + Leak Detection solutions hit their stride

New technology enables problem-solving solutions.

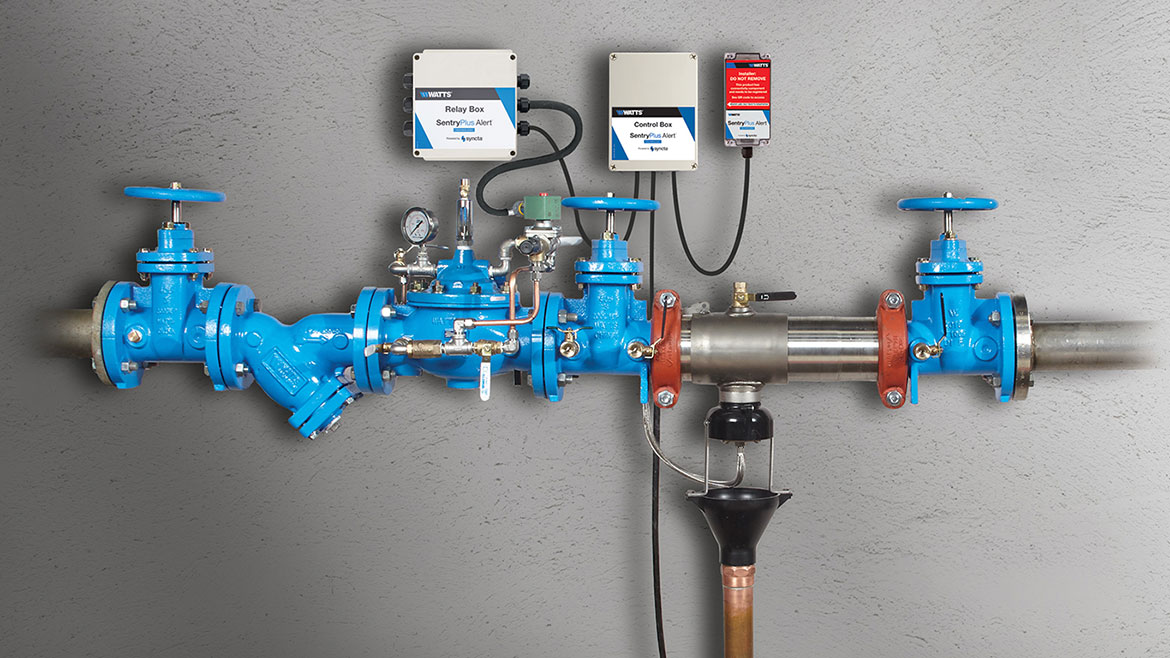

SentryPlus Alert is a connected and IoT-enabled RPZ backflow preventer and flood protection shutdown automatic control valve designed to provide facility managers with 24/7/365 peace-of-mind alerts against flooding because of catastrophic RPZ backflow discharge. All photos courtesy of Watts Water Technologies.

Invariably, these days, it seems there’s always some new technology emerging to solve problems once considered inevitable, tough or impossible to prevent — and with the potential for severe consequences in their wake.

This is very much the case when looking at age-old risks associated with water supply and sprinkler system backflow devices. There’s always the challenge of metal or gasket fatigue, a rupture caused by blunt force, human error or breakage due to freeze. The list goes on and on.

“The plumbing and mechanical industry is more dynamic today than ever before, alive with change and improvement in response to risks, or trends, filling gaps that – just a decade ago – we hardly knew existed,” says Nadeem Mirza, Watts senior product manager, backflow and risers.

According to Mirza, four categories are now seeing a proliferation of new technology. They include:

- leak detection/flood protection;

- fire sprinkler tamper detection;

- performance monitoring of backflow devices; and

- temperature-sensing for backflow assemblies and valves.

In the 150 years since its founding, Watts has learned the importance of investing in emerging technology. The company’s recent investment in connected products and solutions now serve many markets worldwide. Some of the greatest advances have been seen in the categories of backflow and leak detection.

Retired contractor and PM Columnist Dave Yates conducts a backflow prevention test.

Watts embarked on a “Smart & Connected” journey in 2019.

“Our ambition is to transform our portfolio, with key enhancements to those technologies that can be digitally-enabled,” says David Benaiges, vice president, Watts Digital. “The reason for this is to build strong, digital experiences for our customers, offering new and substantive value. We’ve accomplished a lot in the past four years, and now we’re about to achieve our goal: to get 25% of our revenue from smart and connected products.”

According to Jason Perry, Watts channel sales manager — Western region for fire, waterworks and irrigation, “We’re investing in a future that’s moving at a pace unlike anything we’ve known before.”

New backflow technologies

Rick Kelly, national sales manager — fire, waterworks and irrigation for Watts, notes that several key products and technologies — all making an impact in backflow prevention and leak detection — help to illustrate the growth of Watts’ strategic, smart and connected initiative.

SentryPlus Alert is a connected and IoT-enabled RPZ backflow preventer and flood protection shutdown automatic control valve designed to provide facility managers with 24/7/365 peace-of-mind alerts against flooding because of catastrophic RPZ backflow discharge.

The alerts provided by an RPZ backflow preventer come with the possibility of discharge through the relief valve should the valve become compromised. While this is part of the backflow preventer doing its job, it’s an excessive discharge that can cause flood damage to a facility and significant water wastage.

Today, many backflow assemblies on fire sprinkler lines are chained or have an alarm added to them after installation to prevent tampering; Watts’ integrated tamper switch comes preinstalled and is designed to immediately send a signal to the fire panel if someone tries to turn the yoke on the OS&Y gate valves.

Watts’ answer to this need was their recent introduction of SentryPlus Alert — a system that detects potential flood conditions, can shut down the water supply using an automatic control valve and issue multi-channel alerts so action can be taken before major damage occurs. Once installed, the system stands on guard from detection to protection, allowing service managers or building owners to be there, even when they’re not.

Mirza also points out that Watts RPZ’s are shipped with a flood sensor at no charge. The installer needs only to add a cellular or BMS monitoring kit to activate it. Watts also offers a monitoring kit with a sensor for existing RPs. “Hopefully, users will consider all of their existing RPZ’s that could be greatly improved with the simple addition of a retrofit kit,” adds Mirza.

Watts also offers a Cellular Gateway Sensor Connection Kit. Rather than hard-wiring into a BMS (Building Management System) control panel, Watts’ cellular gateway sensor can connect to a local cell signal to transmit an alarm for a water discharge event.

“Using our Sentry Plus application powered by Syncta, a user can build a profile, register and activate their backflow valve, then will have the ability to monitor one or multiple valves in a dashboard,” Mirza explains. “This kind of monitoring is fairly new thinking in the world of backflow valve management.”

The kit comes with two-year subscription service, then changes to a month-to-month subscription fee.

Response time

“Time is of the essence if a discharge occurs. Shortening response time can mitigate damage, and the amount of water lost during discharge incidents,” adds Perry.

• How much time goes by before a discharge event on an RPZ is noticed?

• Consider potential water loss per minute, hour, day — and the cost.

• How long can a backflow be non-operational? Especially a fire sprinkler system. What codes and/or regulations apply? What about any fines?

Speed and efficiency reduce liability

Mirza points to the ability of new technology to monitor multiple backflow preventers, empowering multiple stakeholders with real-time alerts for all their valves in one online dashboard.

SentryPlus Alert detects potential flood conditions and can shut down the water supply using an automatic control valve and issue multi-channel alerts so action can be taken before major damage occurs. Once installed, the system stands on guard from detection to protection, allowing service managers or building owners to be there, even when they’re not.

With cost averages that come from online sources, it’s easy to see the potential repercussions of not utilizing flood sensor monitoring technology.

Commercial water leaks are at fault for damages, on average, of $11,000 to $24,000 per incident. And, if there’s flooding in a commercial facility, Mirza notes that the average cost jumps upwards of $75,000. “Mold can add a 10-times magnifier to that.”

Here in the U.S, statistics show that insurance companies pay out $2.5 billion per year.

The worst of them is the dreaded black mold (aka Stachybotrys atra”). Sadly, discharges can happen 24/7 — and often go undetected.

Fire sprinkler tamper detection

“An important part of this is our new Tamper Switch integrated in our backflow from the factory. It’s an important part of our ‘Smart & Connected’ backflow story and a key solution for our backflow assemblies that are used to supply water to fire protection sprinkler systems,” Mirza says.

Today, many backflow assemblies on fire sprinkler lines are chained or have an alarm added to them after installation to prevent tampering; Watts’ integrated tamper switch comes preinstalled and is designed to immediately send a signal to the fire panel if someone tries to turn the yoke on the OS&Y gate valves. Users need only to wire the switch to the panel eliminating the need for field installation, calibration and testing of tamper switch thus savings field labor hours that can be expensive.

With cost averages that come from online sources, it’s easy to see the potential repercussions of not utilizing flood sensor monitoring technology. Commercial water leaks are at fault for damages, on average, of $11,000 to $24,000 per incident. And, if there’s flooding in a commercial facility, the average cost jumps upwards of $75,000.

According to Mirza, these safety devices indicate an open or closed position of critically important fire sprinkler OS&Y (outside screw and yoke ) gate valves. The switches must be able to signal both tampering and closure of the valve in order to protect the integrity of the system if an effort is made to remove the switch

“Codes require that all fire service system valves be supervised,” he adds. New technology offers this, and more.

Mirza says that backflow tamper detection devices are designed for rigid mounting that’s integrated with the valve. There are no brackets to adjust or tighten. Typically, they’re installed at the factory, and calibrated and tested, while also meeting or exceeding both UL and FM fire codes.

Backflow device performance monitoring

In a similar fashion, new technology offers live pressure readings for backflow assemblies that are sent directly to BMS/BAS to identify potential issues before they become a major health event.

This technology uses connected sensors — reporting pressure conditions continuously (24/7/4 times a second) to alert facility managers of any loss of pressure through integration with the facility’s building management system. Just as valuable, the technology actually allows predictive response so that service to valves, or replacements can be performed before a loss-of-pressure occurrence.

Mirza notes that three sensors give a full picture of backflow health. “This greatly reduces workload associated with visual monitoring, and expedites annual testing of assemblies, as well. They’re especially useful in identifying unauthorized use of water systems, or accidental leakage.”

New Freeze detection kits now provide potential freeze alerts directly to local BMS/BAS or through built in Wi-Fi to identify potential issues before they become a problem.

Temperature-sensing for backflow assemblies, valves and plumbing system

When it comes to risks related to ambient temperatures, freeze protection ranks highest.

New Freeze detection kits now provide potential freeze alerts directly to local BMS/BAS or through built in Wi-Fi to identify potential issues before they become a problem.

Water freezing within pipes and backflows, pressurized vacuum breakers (PVB) is a costly problem. It is not uncommon to see water damage due to freeze that potentially cause catastrophic damage to the pipe or backflow. And, there’s also the risk of backflow contamination in case of check failure.

Smart new technology uses Artificial Intelligence (AI) to monitor the temperature in real time for temperature fluctuations during the night and day. When certain conditions are met, it processes the information and send alerts via Wi-Fi. The unit also has a dry contact that can be used to open/close a water connection.

Conclusion

Plumbing systems have traditionally relied on visual inspection to maintain operational integrity. Lately, however, mechanical rooms have been squeezed into places where facility managers and maintenance personnel rarely travel. At the same time, risks to system impairment have increased.

With the advent of modern technology, systems can be monitored remotely and more effectively in real time, and with data analysis — allowing both alerts and preventive action. This information can be quickly shared via mobile devices and computers.

There’s no doubt, as our world becomes more complex — technologically-connected and dependent on optimal conditions to operate properly — systems of all type and variety are increasingly vulnerable. Catastrophic failure is only a blink away.

We’ve learned here, for instance, of the profound risk of a simple leak. No water leak is simple if complex, mission-critical technologies are in the path of water where it’s not wanted — or if germs and impurities backflow into drinking water.

There are, however, solutions to these increased risks. The greater challenge, it seems, is either ignorance of the potential for problems or their solutions — and failure to apply them.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!