Hydronics Workshop | John Siegenthaler

Comparing air-to-water versus ductless heat pump systems

An alternative to ductless

Image Source: BanksPhotos / iStock / Getty Images Plus

I recently attended a conference hosted by the Building Performance Association. The event attracted many professionals involved with building weatherization, energy program administration and HVAC system performance. Although the 300-plus attendees were not all interested in hydronics, a lot of them were interested in heat pumps, typically ductless air-to-air systems.

I presented a session focused on air-to-water heat pump systems. There was good interest, and several attendees had follow-up questions.

One person, who worked with multiple state and federal energy agencies told me that they’ve had several inquiries about air-to-water heat pumps, but that it was difficult to find qualified installers, and that the cost of an air-to-water system seemed to be significantly higher than a comparable ductless air-to-air heat pump system.

Let's compare

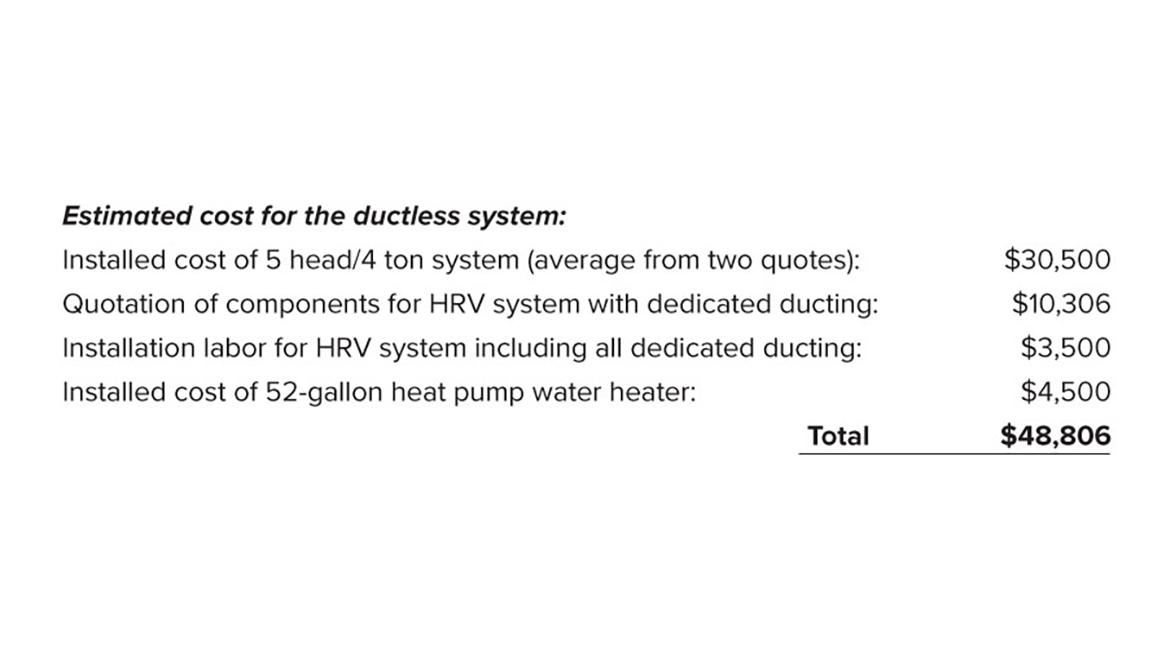

This got me thinking about how the installed cost of a complete HVAC+DHW system based on multi-zone ductless heat pumps for heating and cooling, would “pencil out” relative to that of a system based on an air-to-water heat pump, when both systems were designed for a modern energy-efficient home. What costs would be incurred to provide space heating, cooling, domestic water heating and heat recovery ventilation using each approach, and based on a nominal 4-tons (48,000 Btu/h) of heat pump heating capacity?

The installed cost of any given system will obviously vary, sometimes significantly, based on the company doing the installation, where the project is located, and other constraints imposed by a specific project (i.e. where equipment will be located, difficulty in routing piping/wiring/ducting, local code requirements, etc.).

To build reasonable cost estimates I spoke with two mechanical contractors in very different market areas, and a manufacturer who offered design and direct-to-customer pricing. They provided estimates on installed costs for major portions of the overall system. I also researched components costs from websites that sell direct. Here what I came up with:

The ductless heat pump system would provide 5 independently controlled zones of heating or cooling (but only one mode at a time). Domestic water heating is provided by a residential heat pump water heater. The heat recovery ventilation system had a dedicated delivery system using small diameter flexible ducting routed to several fresh air delivery locations in the house, with exhaust air collection from two bathrooms.

The alternative

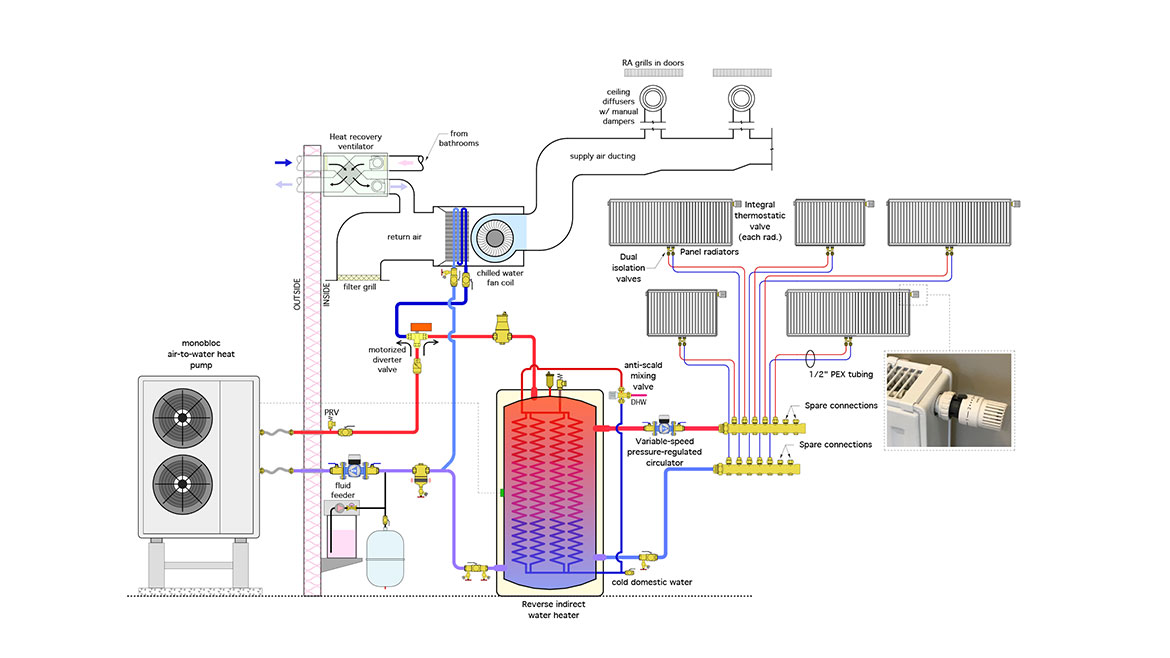

Figure 1 shows a relatively simple system configured around a cold-climate monobloc air-to-water heat pump.

FIGURE 1

Image courtesy of John Siegenthaler

The heat pump supplies heated fluid (e.g. a 30% solution of propylene glycol antifreeze) to a reverse indirect water heater. This tank also buffers a simple homerun heating distribution system serving 5 panel radiators, each equipped with a thermostatic radiator valve (TRV) and sized to provide design load when supplied with 120° F water. All the radiators are supplied through 1/2-inch PEX tubing.

The heat pump maintains the tank temperature between 115° F and 125° F. That’s hot enough to ensure 110 ºF DHW delivery temperature.

A small variable-speed pressure-regulated distribution circulator operates 24/7 during the heating season. It automatically changes speed in response to modulation of the thermostatic valves at each radiator. In this system a small circulator that only requires 44 watts at full speed is sufficient. If electricity costs $0.20/kWh, and assuming that the circulator operates at full speed, its operating cost over 24 hours is about $0.21.

Domestic water is heated as it passes through the heat exchanger coils inside the reverse indirect water heater. If the DHW delivery temperature needs to be higher than 110° F, a small electric water heater could be added downstream of the reverse indirect.

Cooling is provided by a single ducted air handler with a chilled water coil. Supply air travels through ducting, all located within conditioned space, to a series of ceiling diffusers, each equipped with a manually adjustable damper. If interior doors are closed, return air from each room flows through grills at the bottom of interior doors as shown in Figure 2.

FIGURE 2

Image courtesy of John Siegenthaler

These grills, available from Tamarack Technologies, allow air passage while suppressing light and sound transmission. All return air is collected at a single location equipped with a filter grill, and located close to the inlet of the air handler.

The HRV supplies fresh pre-conditioned air directly into the return side of the air handler. The blower in the air handler runs at low speed to create an airflow rate of about 150 cfm when the HRV is operating. Its speed increases to 1,050 cfm when delivering three tons of cooling capacity.

This approach eliminates dedicated ducting for ventilation air. It also minimizes the need for return air ducting. Both of these help reduce system cost without compromising performance.

A 3-way motorized diverter valve directs the flow leaving the heat pump to the buffer tank (in heating mode), or the air handler (in cooling mode).

If the cooling thermostat calls for operation at the same time the buffer tank needs a temperature boost, the latter takes priority. Since this scenario would occur in warm weather, it would only take a few minutes for the heat pump to bring the buffer tank back up to 125° F. During this time the blower in the air handler could continue running, but there would be no cool fluid pass through its coil. As soon as the tank temperature has recovered, the heat pump switches to cooling, the blower turns off for perhaps two or three minutes while the fluid in the heat pump piping is being chilled, and then the blower restarts with chilled fluid circulating through its coil. This control sequence eliminates a short but noticeable “burst” of warm air from the registers when occupants are expecting cooling.

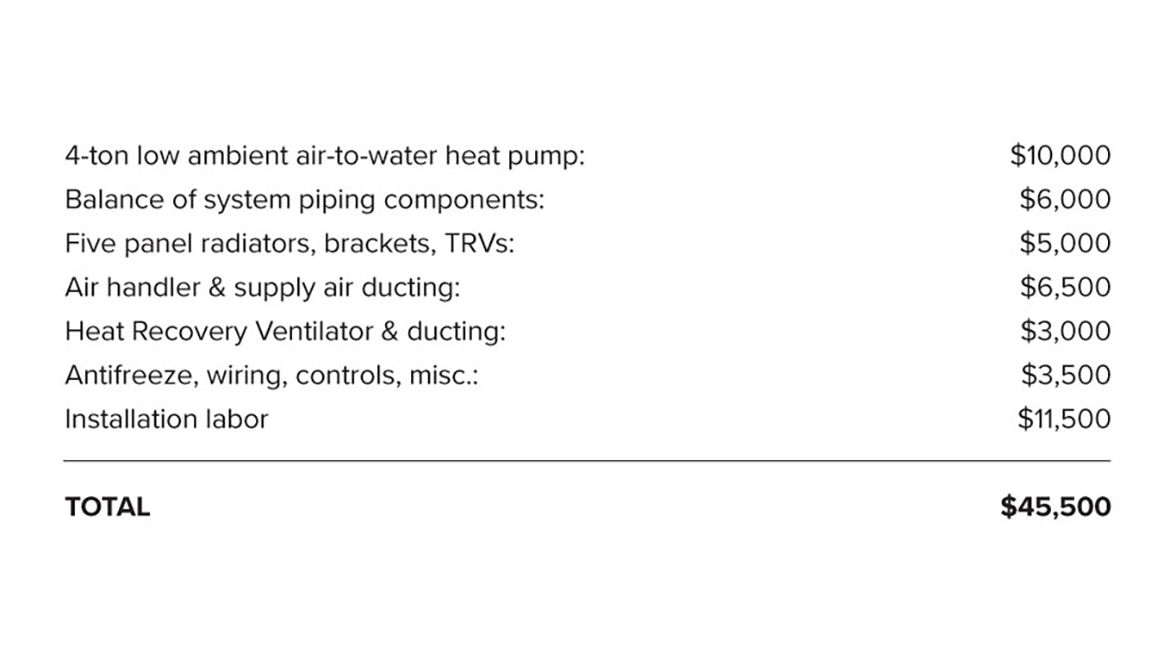

Here are the cost estimates for the air-to-water heat pump system shown in Figure 1:

Your costs for materials and labor may be higher or lower than these estimates. The takeaway is that both systems described above have comparable installation cost.

It’s not all about cost

In my opinion, the hydronic approach offers some additional benefits relative to the ductless approach:

1. There is only one cooling coil and one filter to maintain compared to five separate coils and filters with the ductless system. Cooling coils and condensate drains need to be periodically cleaned to prevent mold from accumulating. Mildew can also form on the inside surfaces of ductless heads, and it needs to be removed. The hydronic approach reduces this maintenance requirement to a single location that’s not within the living spaces of the house. For context, companies that specialize in cleaning ductless heat pump systems charge about $600 to clean a 5 head system with a single outdoor unit.

2. Ductless wall cassettes transfer all heat output by convection (e.g., a forced air stream). Panel radiators emit both convective and radiant heat. The lower the water temperature at which the panel rads operate, the higher the radiant output as a percentage of total output. This improves comfort by warming other interior surfaces near occupants.

3. Each ductless wall cassette has a blower. These blowers have been engineered to be relatively quiet, but in my experience, they’re still loud enough to be objectionable in situations such as conversations between persons with impaired hearing or watching TV at low volume levels. Panel radiators are completely silent.

4. The net COP of a heat pump water heater that draws its heat from an interior space that’s heated by another heat pump will be significantly lower than its rated COP. See my previous PM column “Cascading Heat Pumps” from January 2021 for more information. This gives the efficiency edge for domestic water heating to the air-to-water heat pump.

5. The air-to-water heat pump system only requires one tube set penetrating the building’s exterior wall. A five head ductless system requires five line sets that must each penetrate from outside to inside at some location. Figure 3 shows an example of what the piping near the outdoor unit can look like.

FIGURE 3

Image courtesy of John Siegenthaler

6. All air-source heat pumps have to periodically defrost their outdoor evaporator coil. With the hydronic system the heat required for defrosting comes from the buffer tank and its transfer is unnoticeable to the occupants. With the ductless system, the heat required for defrosting comes directly from inside air. That air has very little thermal mass. Trust me — defrosting during cold weather is noticeable to occupants.

7. The hydronic portion of the system is unaffected by ongoing refrigerant phase-outs. If a new air-to-water heat pump has to eventually be installed there would be little if any change to the hydronic portion of the system. With a ductless system you’re betting that a drop-in replacement refrigerant will eventually be available that will not require changes to piping, lubricating, oils or concerns over refrigerant flammability.

8. The hydronic system using a monobloc heat pump can be installed and commissioned without refrigeration tools or skills. The heat pump is factory-charged and leak-tested. With a five-zone ductless system there are a minimum of 20 mechanical flare joints in refrigeration tubing. The potential for refrigerant leakage is higher.

9. If you look carefully at the manifold station in Figure 1 you’ll see provisions for two additional circuits. This is an easy “upsell” that adds very little to the system’s initial cost but makes it easy to add heat emitters, such as a towel warmer, or another panel radiator in the future. Just run a couple of 1/2-inch PEX tubes from these spare connections to the new emitter and open the manifold valves. If only it was that easy to add another head to a multi-head ductless system. It’s not. In most cases, the number of refrigerant circuits on the outdoor unit is matched to the number of heads installed with it. Adding another head requires adding a new outdoor condenser unit, and that’s going to cost several thousands of dollars.

Get ready

Ductless heat pump systems continue to be specified for many low-load and net-zero homes. They work, but not without compromises. The perception that they have significantly lower installation costs than air-to-water heat pump systems with comparable capabilities is not necessarily true.

What is true is that the number of HVAC pros who are ready, willing and able to install air-to-water heat pump systems is currently well below what the market, driven by accelerated electrification targets, needs. That situation is gradually improving as more air-to-water heat pump products enter the North American market, and manufacturers expand their training efforts. If you provide professional design or installation of hydronic systems I urge you to consider the market opportunity that’s before you.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!