Christoph Lohr: Plumbing engineering industry outlook

Plumbing science is shifting quickly.

ljubaphoto/E+ via Getty Images.

“In a knowledge-based economy (that is an economy which is directly based on production, distribution and use of knowledge and information) requires knowledge-based workers… and that knowledge work is effective if only it is highly specialized (e.g., what makes a brain surgeon effective is that he is highly specialized in brain surgery, but by the same token couldn’t repair a damaged knee and would probably be helpless if confronted with a tropical parasite in the blood). This is true for all knowledge work. Generalists… are of limited use in a knowledge economy. In fact, they are productive only if they themselves become specialists in managing knowledge and knowledge workers. The knowledge needed in any activity has become highly specialized. It is therefore increasingly expensive and difficult to maintain enough critical mass for every major task in an enterprise. And because knowledge rapidly deteriorates unless it is used constantly, maintaining within an organization an activity that is used only intermittently guarantees incompetence.” — Peter Drucker, On Management, 1974

If you follow me on LinkedIn, you know I am passionate about advocating for plumbing engineers and designers. I have regularly written about the need for plumbing engineers, especially in solving our various water crises and improving our medical gas systems. The lesson is clear: plumbing systems are continually increasing in complexity.

I am reminded of a recent interaction I had with a director of engineering (DOE) about plumbing versus HVAC design. This particular DOE indicated to me how, for HVAC design, there are design and construction cost efficiencies in utilizing a singular 12x12 duct with 6x6 diffusers located on the side of the duct, rather than downsizing the 12x12 to a 10x10 and then to an 8x8. He asked me what I thought of doing the same thing with water piping. He was shocked (and perhaps disappointed) when I said that if anything, plumbing was going to go the opposite direction, with much more fine-tuning and right-sizing of water systems, due to waterborne pathogens and water sustainability concerns.

David LeFrance, CEO of AWWA, says it best: “People think that water is simple, but it is highly complicated.” I agree, although water is only one of the concerns with which plumbing engineers deal — sanitation, medical gas and storm systems all are increasing in their requisite knowledge.

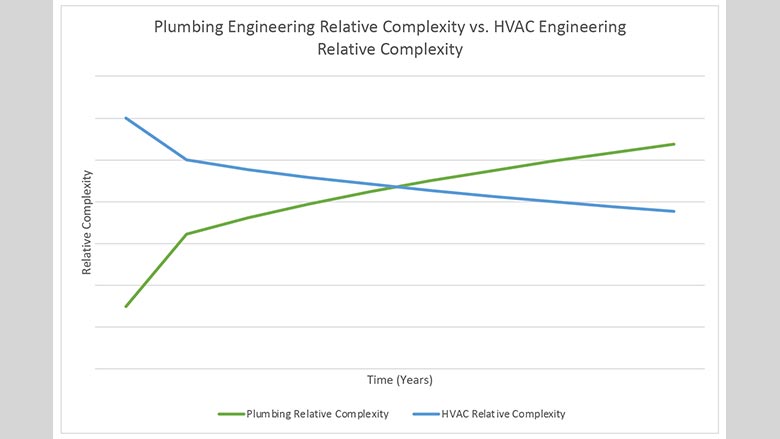

If you were to put in graphical form what I am describing, it would likely look as follows:

This inversion is occurring rapidly. If MEP firms are not prepared, they will be in a terrible position in the near future. The risks of not recognizing this plumbing shift for MEP firms includes increased staff burnout and turnover, underbidding projects and lost revenue opportunities and increased litigation risk and insurance payouts. Simply put, engineering firms need to be extremely aware of what is going on in plumbing right now. There are driving factors in water, especially in water safety and water conservation. Education and specialization will be key moving forward in making sure the right expertise is applied.

Water safety and water conservation

Water safety and water conservation are the two most pressing issues. Further challenging is the fact these two realms have some friction points between them, especially as water age becomes a more and more concerning water quality metric (e.g. NASEM indicated in 2019 that low-flow fixtures should not be utilized in healthcare facilities due to an increase in risk of waterborne pathogen infection from increased water age).

Fortunately, there are several ways the industry has been responding to these concerns. One worth highlighting, for those of you who may not be aware, is the IAPMO/ANSI Water Efficiency and Sanitation Standard (WE•Stand). The publication of WE•Stand is noteworthy as it is the first standard that focuses on achieving safe and efficient water use in both residential and non-residential buildings. Water is critical to our nation’s health, environment, security and resilience, but the solutions available for communities to maximize water efficiency historically have not kept pace with innovation, and sometimes have jeopardized safety. WE•Stand changes that by bringing together the most advanced measures to help communities efficiently use available water resources and take advantage of alternate water sources while improving public health.

Two themes of the provisions in WE•Stand worth mentioning here include water reuse and water right-sizing. By implementing water reuse systems, buildings can significantly reduce their water usage. Water reuse systems collect and treat water that has been used for one purpose, such as showering or hand washing, and then reuse it for another purpose, such as toilet flushing. In building environments where reducing the water age in hot water systems in a concern (I.e. ASHRAE 188), water reuse could help unlock the ability to flush those systems and still find ways to repurpose the water. According to the EPA, implementing a greywater reuse system can reduce a building’s water usage by up to 40%. Water reuse provisions have existed in WE•Stand since 2017. Additionally, right-sizing of plumbing systems also promotes safety and sustainability by reducing water age and promoting efficiency. Introduced in the 2017 WE•Stand, the IAPMO Water Demand Calculator (WDC) utilizes data to validate the right sizing of residential occupancy water systems. Since then, IAPMO has continued to work on expanding the WDC into commercial buildings. We continue to get closer to making this exciting leap.

Professional development

ANSI standards and product certifications are important to plumbing safety and sustainability, and so is professional development. There are several efforts out there to show enhanced understanding of plumbing system engineering.

The first is the ASSE 12000 series certification. For engineers, worth considering is the ASSE 12080, a certification for individuals who specialize in Legionella risk mitigation. This certification program ensures individuals have the necessary knowledge and skills to develop, implement, and manage Legionella control strategies in building water systems. With the increasing concerns about Legionella outbreaks, this certification is becoming exceedingly important for plumbing engineers. The ASSE 12060-12063 certifications qualify contractors and tradespersons to participate on building water management teams. These certifications afford a verification and validation path to compliance with standards and guidelines related to cooling towers, water features, potable water systems, fire protection, ice machines, humidifiers and all piped systems that currently reside in all occupied buildings. The 12060-63 series was recently added to ASPE’s Engineering Methodologies for Reducing the Risk of Legionella in Premise Plumbing Systems, otherwise known as the ASPE Legionella Design Guide, for inclusion in engineering specifications.

In building construction and design, MEP firms cannot practice without a licensed professional engineer as their principal. This is required by licensing laws and administrative statutes nationally. Therefore, any professional who wants to open their own firm or become a principal at a firm at which they work is required to take and pass an examination. It is not fair to mechanical engineers who have specialized in plumbing rather than HVAC to not have an examination that tests them on their knowledge, especially if not obtaining a PE is so detrimental to their career and livelihood.

Another established credential for consideration is ASPE’s CPD, a certification for plumbing engineers that covers various aspects of plumbing design, including piping, drainage, fixtures, and fittings. The program covers both the theoretical and practical aspects of plumbing design, ensuring that individuals have a comprehensive understanding of the subject. Plumbing engineers who have earned certifications such as the ASSE 12080 and/or CPD provide added value to building owners and developers by ensuring they have the necessary skills and knowledge to design safe and compliant plumbing systems. By having specialized certifications, they can provide expertise in specific areas of plumbing, such as Legionella risk mitigation. This expertise can help owners and developers ensure their buildings are safe, efficient and compliant with industry standards.

The other vital effort by ASPE includes the efforts of its Plumbing Engineer Working Group (PEWG). ASPE established the PEWG to develop a program for the placement of a plumbing option within the framework of the Mechanical Engineering Principles and Practice (MEPP) examination, as developed by the National Council of Examiners for Engineering and Surveying (NCEES) and administered by the various state boards of registration/licensure. In building construction and design, MEP firms cannot practice without a licensed professional engineer as their principal. This is required by licensing laws and administrative statutes nationally. Therefore, any professional who wants to open their own firm or become a principal at a firm at which they work is required to take and pass an examination. It is not fair to mechanical engineers who have specialized in plumbing rather than HVAC to not have an examination that tests them on their knowledge, especially if not obtaining a PE is so detrimental to their career and livelihood. This sentiment was shared with me by an EIT in Utah: “I have experienced firsthand the need for a plumbing option within the mechanical engineering examination. Before graduating in mechanical engineering from the University of Utah, I worked in the plumbing construction industry for many years. Since graduation, I have worked as a mechanical engineer designing the plumbing construction plans for various commercial buildings in Utah and surrounding states. My next career step is to become a licensed professional engineer. Despite having 10 years of design and applied experience in plumbing, I am currently studying to take the HVAC mechanical engineering exam because a plumbing exam is not available. I will be tested on systems unrelated to my career and expertise.”

Introducing a plumbing-option exam would provide an opportunity for plumbing engineering professionals to demonstrate their specialized knowledge and expertise. It would also provide a clear benchmark for aspiring plumbing engineers to strive toward, incentivizing them to develop their skills and knowledge in this area. Moreover, it would help to promote the importance of plumbing engineering and raise awareness of the value it brings to society.

Conclusions

Plumbing science is shifting quickly. The challenges of water conservation and water safety are just two examples of plumbing resiliency concerns. Understanding water quality will also become more crucial for plumbing engineering professionals moving forward. Therefore, professional development in the form of plumbing certifications and plumbing engineering licensing will be vital to help meet these challenges. But that won’t be enough. We need to change the conversation about plumbing engineering, and I have some ideas to do so — but more on that in my next article.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!