Commercial kitchen ventilation in the UMC

Follow code requirements to ensure a clean, functional, efficient and safe large-scale cooking operation.

Photo credit:©Gettyimages.com/izikMd

The kitchen serves as the heart and soul of a commercial cooking operation. Commercial kitchens provide a means of preparing food for the public in large quantities. Because of this high volume of service, large-scale cooking establishments require proper design, construction, operation and maintenance of ventilation systems. Such systems are used to effectively manage grease vapors, odors, contaminants and moisture within the air, as well as toxic and combustible gases, such as carbon monoxide.

When all of a ventilation system’s various components work together harmoniously in such establishments, the system helps control temperature, humidity and airflow, protecting patrons and employees by improving indoor air quality and minimizing potential hazards. The 2021 Uniform Mechanical Code (UMC) contains all of the necessary requirements for the safe installation of a commercial kitchen ventilation and exhaust system.

General requirements

The requirements for commercial kitchen ventilation systems may be found in Chapter 5, Part II of the UMC, extracted in part from NFPA 96, and provides guidance for commercial kitchen hoods, grease ducts, fire-extinguishing and suppression systems, exhaust fans, makeup air and maintenance, to name a few. Unlike domestic kitchens, which typically do not require a hood above a range and where ventless and recirculation systems have become common, commercial kitchen settings require an appropriately sized ventilation system with an approved hood.

Hoods

One of the most critical pieces of equipment within a large-scale kitchen is the commercial exhaust hood and the grease removal devices in it. Commercial hoods are necessary for extracting smoke, microscopic grease-laden vapors, fumes and nuisance odors from the cooking area. If these airborne contaminants and irritants are not removed, the kitchen environment can become intolerable and even nauseating for those within the space. The harsh environment of a commercial kitchen requires high-performance hoods that can handle a vast number of contaminants within the space to meet necessary ventilation requirements for safe operation.

There are two main types of exhaust hoods used in commercial kitchens to remove impurities: Type I and Type II. Type I hoods, often referred to as grease hoods, are required to be installed above equipment or appliances that generate grease or smoke. Type II hoods, or condensate hoods, are required to be installed above appliances or equipment that generate steam, heat or products of combustion. Condensate hoods are utilized for areas where grease and smoke are not present, such as high-temperature industrial dishwashers and pasta cookers. Type I hood exhaust system requirements are addressed in Section 507.0 through Section 518.0 of the UMC, and requirements for Type II hood exhaust systems may be found in Section 519.0. Grease-removal devices are covered in Section 509.0, “Grease Removal Devices in Hoods.”

Ducts

Type I ducts, or grease ducts, are used as the conduit for flammable and contaminated air to safely travel from indoors to outdoors, and are addressed in Section 510.0. It is crucial that the fire rating of a commercial kitchen not be compromised. Therefore, when ducts penetrate a fire-rated wall or ceiling, a continuous enclosure must be provided, except where a field-applied or factory-built grease duct enclosure is protected with a listed duct-through-penetration system equivalent to the fire resistance rating of the assembly being penetrated, as stated in Section 510.7.

It is typical for multiple Type I hoods to share common ductwork. Section 513.3 through Section 513.3.5 provides specific requirements for simultaneous operation when a common duct serves more than one cooking appliance. Depending on the distance from the common duct to the farthest hood, hoods installed back-to-back or end-to-end may require simultaneous or independent operation of the fire extinguishing system. A restriction to combining such ductwork is found in Section 510.1.2, “Interconnection,” which prohibits Type I duct systems from being interconnected with other building ventilation or exhaust systems in order to prevent cross contamination of grease, lint and other contaminants, which may transfer and accumulate within the exhaust ducts and pose a fire hazard. Type II exhaust duct systems, referenced in Section 519.4, must comply with the duct requirements found in Chapter 6.

Fire protection systems

Because commercial kitchen ventilation systems present a greater fire risk than other ventilation systems, a fire-extinguishing and suppression system is always required per Section 513.1.2, “Protection.” Section 513.0, “Fire Extinguishing Equipment,” provides various methods to be used to protect cooking equipment and appliances during operation. When hoods are installed adjacent to each other or share common ducts and do not exceed 75 feet in distance from the farthest hood, all hoods and ducts require simultaneous automatic fire protection. If the distance exceeds 75 feet, an independent fire-extinguishing system with its own detection system or simultaneous automatic fire protection in all hoods and ducts is required. For added fire protection, the UMC also requires that a Type I hood exhaust system terminate directly to the outside of the building via an exhaust fan or duct, either through the roof or wall. This safety measure must be taken to minimize fire hazards to other parts of the building in the event of a fire. Additional termination requirements can be found in Section 510.9 of the UMC for Type I systems or Section 519.5 for Type II systems.

Exhaust rates

Minimum general exhaust rates may be found in Table 403.7, “Minimum Exhaust Rates,” which states a minimum exhaust rate of 0.70 cfm/ft² is needed in commercial kitchens. Commercial hoods have their own exhaust rates, which may be found by using Table 508.5.1.2 through Table 508.5.1.5, depending on the type of appliance and hood used, and whether the cooking appliance is categorized as light-, medium-, heavy-, or extra heavy-duty. There are some exceptions for the use of Type I hoods, such as appliances with reduced emissions and recirculating systems in compliance with UL 710B.

Makeup air

Since the exhaust system removes both clean and contaminated air from the kitchen space, a supply of makeup air, also known as replacement air, must be provided as indicated in Section 511.3, “Makeup Air.” Makeup air is required to replace the air that is removed from the kitchen through the exhaust hood, dilute gas temperatures and prevent building air pressures from exceeding 0.02 of an inch of water column. This keeps the kitchen under slightly negative pressure to prevent cooking odors and contaminants from migrating into adjoining spaces. Makeup air is just as important to the food service operation as the exhaust rate. Without adequate ventilation and a sufficient supply of clean makeup air, a commercial kitchen would not be able to operate safely or efficiently.

Access and maintenance

Grease can quickly accumulate and build up within hoods, ducts and filters, creating one of the most common causes of commercial kitchen fires. This safety hazard can be significantly reduced with proper maintenance and cleaning. Moreover, for certain fire extinguishing and suppression methods, a damper is needed in the exhaust duct to reduce oxygen in case there is a grease fire within the grease duct.

These dampers, along with the other components of the ventilation system, must be kept clean and in good working condition. For this reason, easy and safe access for inspection, cleaning and maintenance is necessary and required. Unobstructed access panels (doors) allow for such maintenance of the system and are addressed in Section 510.0, Section 512.0 and Section 514.0. Maintenance of the commercial kitchen ventilation, exhaust and fire extinguishing systems must be completed at least every six months. Details pertaining to this type of maintenance may be found in Section 514.2, “Inspection, Testing and Maintenance.” When properly cared for using the guidelines in the UMC, these systems work together harmoniously to help commercial kitchens operate at their full potential.

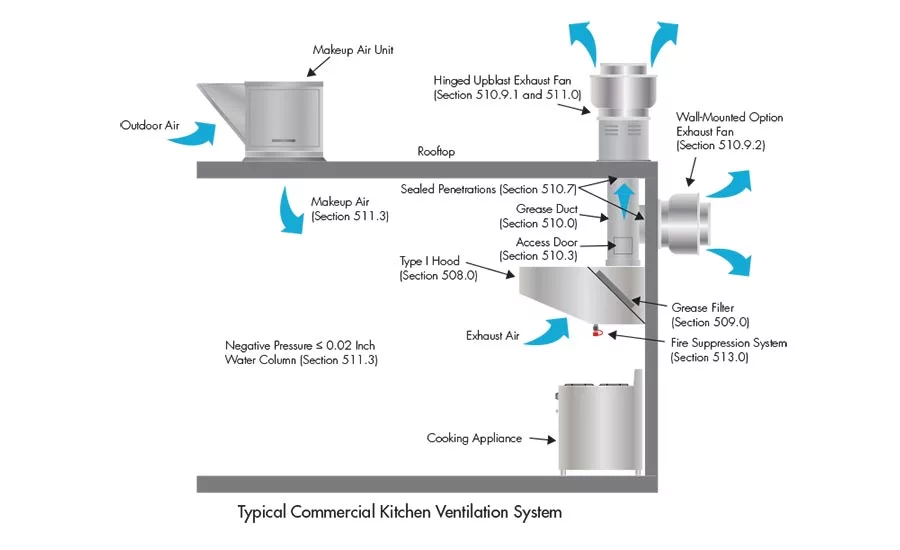

As shown in Figure 1 below, the UMC provides all of the necessary safety installation requirements for the commercial kitchen exhaust system.

When commercial food service operations fail to comply with industry codes and standards, the indoor air quality will be compromised. The commercial kitchen ventilation guidelines found in the UMC include provisions from NFPA 96, as this industry standard has proven to be an excellent source of design, installation and maintenance requirements for commercial kitchen ventilation systems. Familiarity with the guidelines in the UMC when designing, constructing or operating a commercial ventilation system contributes to a clean, functional, efficient and safe large-scale cooking operation. The use of the UMC allows both installers and inspectors to be well equipped with the necessary guidelines and provisions to enhance the overall safety and comfort of commercial cooking environments.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!