Renewable Heating Design | John Siegenthaler

Complementary fuel sources

Progression to renewably sourced energy should not be immediate, or exclusive to fossil fuels.

Image courtesy of baranozdemir / iStock / Getty Images Plus.

Almost every level of government, from the feds down to the local city councils, are enacting legislation that favors electricity over any type of fossil fuel. Some regulations, such as those in New York State, plan to sunset all fossil fuels in new construction after 2025.

The “flames” associated with electrification versus fossil fuel have been fanned by politics — a place where reality is a very fluid concept. As has happened with many other issues — deep divides have been created between people depending on their worldview, profession, willingness to accept technical realities and opportunities to profit from a stance on either side of the issue.

Like most people, I have opinions and beliefs about our current energy sources, and specifically how they play into the future of hydronic heating and cooling technology. The title of my PME column, “Renewable Heating Design,” points to my belief that our industry can and should increase its use of renewably sourced energy. However, it doesn’t imply that such a progression should be immediate or exclusive of fossil fuels.

Merged benefits

With the above in mind, let's consider the merits of pairing an electrically-operated air-to-water heat pump with a fossil fuel-fired boiler. Systems using both heat sources can be designed and installed in either new and retrofit applications. Given the vast number of fossil fuel boilers already supplying hydronic systems, it’s likely, in the near term, that retrofit applications where an air-to-water heat pump is added to a system already supplied by a boiler will be common.

Keep it

I’ve interacted with people who think that fossil fuels are the scourge of the earth, public enemy No. 1 and, as such, any equipment operating on these fuels should be immediately scrapped. I suspect that such mindsets are based on socio-political leanings rather than practical and technically accurate (or realistic) assessments of alternatives.

Sure, some boilers have been patched up to hobble along “one more season” while operating at conditions that are far from optimal. Like any device, all boilers eventually succumb to a life of hot, wet and chemically reactive conditions, often with minimal maintenance. Good technicians can assess the status of an existing boiler, and when they conclude the boiler is at the end of its service life, recommend it be removed. They can also determine when an existing boiler has remaining service life and judge its suitability to remain in the system as an occasionally used “copilot” to a new air-to-water heat pump.

Consider the advantages of keeping such a boiler in the system.

1. Booster: The boiler can provide supplemental heat for the heat pump on very cold days when the heat pump’s capacity cannot meet the load. Without it, many owners would resort to portable electric space heaters, the operation of which, when accounted for back to the electrical generation level, likely contributes more carbon to the atmosphere than burning the fossil fuel needed to supplement the heat pump.

2. Backup: Assuming the boiler was adequately sized, it can provide full backup heating when the heat pump is down for service. Modern heat pumps are complex devices. It’s unrealistic to think they will operate for 15 to 20 years without any issues that would take them offline for a time. Depending on the location of the system, who is responsible for servicing it, and the availability of replacement components, it’s also unrealistic to think that the repair will always take place within hours of the problem’s occurrence. It might be several days. Most owners who understand this also understand they need a “plan B” for heat should the problem occur in cold weather. They already know the existing boiler can heat the building. Encourage them to incorporate this known entity into the system makeover.

3. Major contributor: Simulations of air-to-water heat pumps in cold (upstate New York) climates have shown that the vast majority of seasonal space heating energy required in a typical home can come from the heat pump. The boiler may only contribute 5-15% of that total seasonal energy depending on the supply water temperature required by the distribution system (lower is always better), and the capacity of the heat pump relative to the building’s design load. In my opinion, that’s a very respectable shift away from fossil fuels without sacrificing reliability, comfort, or scrapping equipment that still has several years of remaining service life. Furthermore, the cost to remove and dispose of a boiler, fuel system and chimney that still have service life, and replacing it all with an electric boiler for auxiliary/backup, only adds to the installation cost of the heat pump, and thus discourages potential customers.

4. Service entrance upgrades: Another necessary consideration for full electrification is the ampacity of the building’s service entrance. Older homes with fossil fuel boilers may only have 100 or 150 amp services. Adding a heat pump to these services may be possible, depending on its capacity, and the existing loads on the service. However, adding a heat pump and an electric boiler sized to meet the building’s design heating load will inevitably require a minimum 200 amp service. Include an electric vehicle charger in addition to the heat pump and electric boiler, and the service entrance ampacity could be even higher than 200 amps. Given the current cost of electrical hardware, upgrading a service entrance could easily cost several thousands of dollars. If the existing fossil fuel boiler is retained as the supplemental/backup heat source service entrance upgrades may not be required.

5. Futureproofing: It’s easy to plan a new or retrofit installation so that a fossil fuel boiler could eventually be replaced by an electric boiler if and when that becomes economically viable. This can be done with minimal piping alterations, and without draining the system. Just be sure to include isolation and purging valves when connecting the fossil fuel boiler to the remainder of the system.

6. Resiliency: Leaving an existing fossil fuel boiler in the system provides the ability to keep the building’s heating system running — perhaps for several days, without utility power. During a utility power outage, a typical residential fossil-fuel boiler and two or three circulators can be powered from a small portable generator that costs less than $1,000. Provisions for connecting such a generator to the heating system are relatively simple and could be included in the installation. The fossil fuel mode of the system could also be powered from modern customer-side battery storage systems such as the Tesla Powerwall or Generac PWRcell.

A nominal 5-ton (60,000 Btu/h) heat pump and its associated distribution system could also be powered by a generator, but likely one with a minimum output of 10KW. Add in 9KW of electric resistance backup or supplemental heating, and you’re up to a nominal 20KW generator as a minimum. It can be done, but it’s expensive to install and operate.

7. Adaptability: Many electric utilities have, or soon will have, time-of-use electric rates in their offering. In essence, these rates offer a discount on each kilowattt•hour (KWh) of electricity purchased during specific times of the day, as well as on weekends and most holidays. Utilities do this to help level their demand curve. Some on-peak versus off-peak differentials are very attractive. I recently heard of one New England utility offering off-peak electricity at $0.07/KWh but with an on-peak rate of $0.44/KWh. The high on-peak rate creates a strong disincentive to operate high-demand electrical devices whenever it’s in effect.

If the system includes a fossil fuel boiler, it could supply heat when necessary to minimize use of on-peak electricity. The air-to-water heat pump could be operated on the low-cost off-peak rates. Thermal storage might also be included in the system.

Utility rate structures are rapidly evolving to keep up with projected demand while minimizing the need for significantly greater generation and transmission capital costs. A dual fuel system provides the flexibility to leverage these rate structures.

Parallel piping

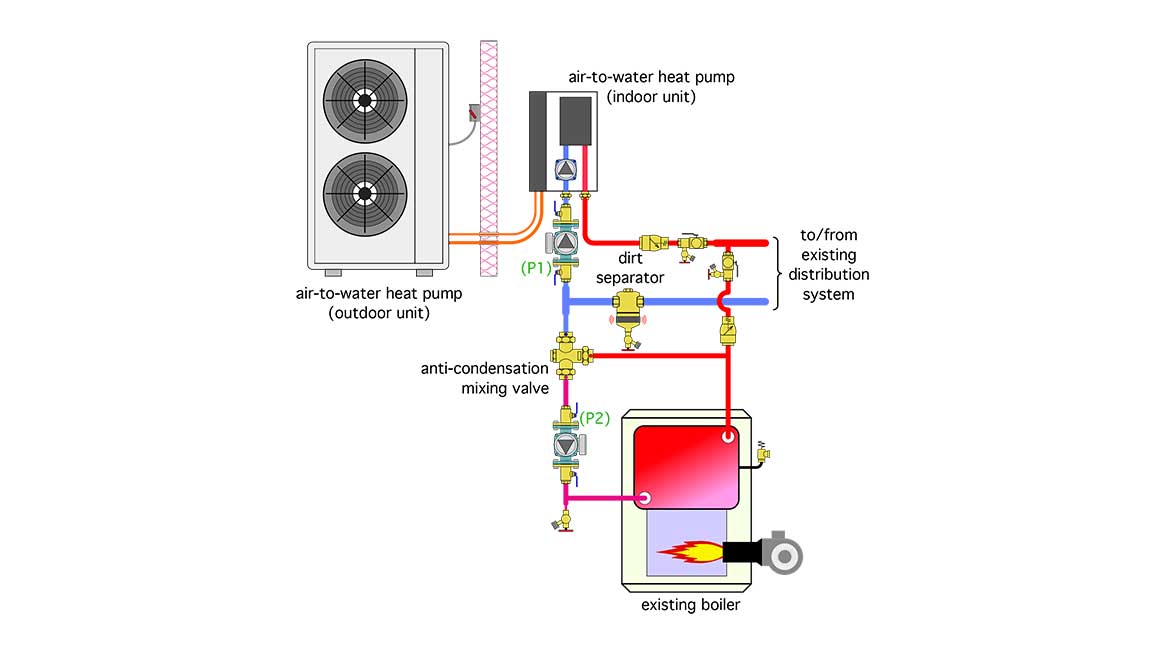

Figure 1 shows a possible piping configuration where a split system air-to-water heat pump is piped in parallel with an existing fossil-fuel boiler.

FIGURE 1

This configuration allows either heat source to operate independently of the other. A typical control sequence would call the heat pump to supply the required water temperature to the distribution system whenever possible, and bring on the boiler only when the heat pump cannot maintain the necessary target supply water temperature.

Notice that the existing (conventional) boiler has an anti-condensation valve added to its near boiler piping. It’s there to prevent sustained flue gas condensation, assuming that there will be times when the return water temperature from the distribution system is below the dewpoint of the flue gases. Existing boilers and their venting pipes that have operated at higher temperatures, and lasted for years under these conditions, can be trashed in short order if “reassigned” to produce low water temperatures, and not protected from sustained flue gas condensation.

Figure 2 shows a similar arrangement — only using a monobloc (rather than split system) air-to-water heat pump. In most applications, this system would operate with an antifreeze solution to protect the heat pump from freezing.

FIGURE 2

Figure 2 shows both heat sources supplying a buffer tank. This is appropriate when the distribution is divided into many small, independently controlled zones. When fewer zones are present, and the heat pump has a variable-speed compressor, the buffer tank could be replaced by a hydraulic separator. In applications where the heat pump and boiler have high turndown ratios, it may even be possible to eliminate the buffer tank or the hydraulic separator and pipe the heat source headers directly to the distribution system. These same concepts hold true in applications using split system air-to-water heat pumps.

Strength through diversity

Although some advocate that all energy needs can be met through electrification, the peak demand situation remains an inevitable hurdle, one that hasn’t been thoroughly and honestly addressed to date, especially within the political realm. As mandates for electrification progress this issue will repeatedly separate aspiration from realization.

As this all plays out, the versatility of modern hydronics technology provides a flexible and adaptive framework upon which to build future heating (and cooling) systems. It allows realistic and beneficial combinations of electrical and fossil fuel energy for the present as well as the years ahead.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!