Contractor's Corner | Dave Yates

Wet vents: Take full advantage of the minimum standards set forth in plumbing code books

Illustrations by Courtney Fathers / Plumbing & Mechanical

If you really want an honest, if not brutally frank, opinion: just ask professional plumbers! Every time I see the subject of using wet venting in an online plumbing forum, several keyboard warriors present themselves in full battle gear with a take-no-prisoners attitude. Visceral hatred for perceived shortcutting of “proper” venting boils over along with righteous indignation directed towards code bodies for allowing such nonsense.

Here’s where the rubber meets the road: if you’re bidding against another plumber who has a good grasp of the plumbing code and who utilizes and applies wet venting, while you remain committed to venting every single fixture, most likely you’re going to lose that bid. The wet vent plumber will use fewer materials and less labor for the same installation.

Illustrations by Courtney Fathers / Plumbing & Mechanical

The plumbing inspector needs to be educated and up-to-speed with the codes they are enforcing, too. On the very first day as a township plumbing inspector, our bathroom remodel in the owner’s suite, with his and her bathrooms, we not only utilized a wet vent for his master bath, we also utilized a neat trick in order to avoid extending the new wet vent through the slate roof. An existing 3-inch vent pipe was just a few feet away and downhill from our lavatory dry-portion of the wet vent. Once more than 6-inches above the flood-level-rim of the sink, we simply turned the dry vent downward to run with the steep pitch of the roof, cut in a 3x2 wye (y pointing upward) to receive the 2-inch vent. Given that no belly/trap was created with both sides free to drain away any moisture/water, it was a code-approved venting method. Pity the poor plumbing inspector whose first real inspection included something he found very confusing. Saying he wanted time to think it over before passing our installation, he left the job. The drywaller called a day later asking if he could continue his work and the general contractor was pushing hard because he too had a schedule to maintain. I called the plumbing inspector who said he was not going to approve the installation! I asked him to get out his code book and together we read through the code passage several times. I strongly suggest you spend the extra money on the plumbing code commentary edition because after each code rule, there follows an interpretation regarding how that is to be enforced and why. The inspector still did not understand the installation and simply could not grasp the fundamental issue of airflow within the vent piping. When I noted this was a method taught to us during plumbing night school by the same instructor he had, he relented and passed the work. I’ll add that, as time passed, he became one of the best most knowledgeable plumbing inspectors in our area.

What is the primary purpose of properly sized and installed plumbing venting? To protect the minimum 2-inch deep trap seal and in order to do that, pressure and/or vacuum must not exceed 1-inch of water column. Pressure can be exerted against the trap seal by the slug of air being pushed ahead of a sudden larger flow, like when a toilet is flushed, or even by wind as it travels across a roof vent. The roof itself can cause lift forces, the same forces that cause planes to fly, and you have probably observed water in a toilet bowl rocking back and forth when it’s windy outdoors.

If you’re bidding against another plumber who has a good grasp of the plumbing code and who utilizes and applies wet venting, while you remain committed to venting every single fixture, most likely you’re going to lose that bid.

Sizing matters! In my area (Southeastern Pennsylvania), the code accepted by our AHJ (authority having jurisdiction) is the IPC (International Plumbing Code). Starting with the fixture vent, maximum distance from the trap to the vent is 5-feet for 1.25-inch, 6-feet for 1.5-inch, and 8-feet for 2-inch at 1/4-inch of fall per foot in the direction of flow.

Next up for consideration is the DFU (drainage fixture load) of the fixture draining into the wet vent for the bathroom group. A single lavatory sink with a 1.25-inch outlet is rated at 1-DFU. You can use a 1.5-inch dry vent rated for 1-DFU, which can continue as the wet vent for a single bathroom group with a maximum of one upstream fixture draining into the horizontal wet vent before finally joining the water closet drainage line. The branch drain from the water closet serving the balance of connected fixtures is sized according to the connected DFU load. A standard bathtub is rated at 2-DFU, however, showers, especially spa-like showers with multiple wands, heads, and body sprays is rated based upon total flow rates and range from 2- to 6-DFU. The IPC Table 709.2 dictates horizontal fixture drain size based on DFU load.

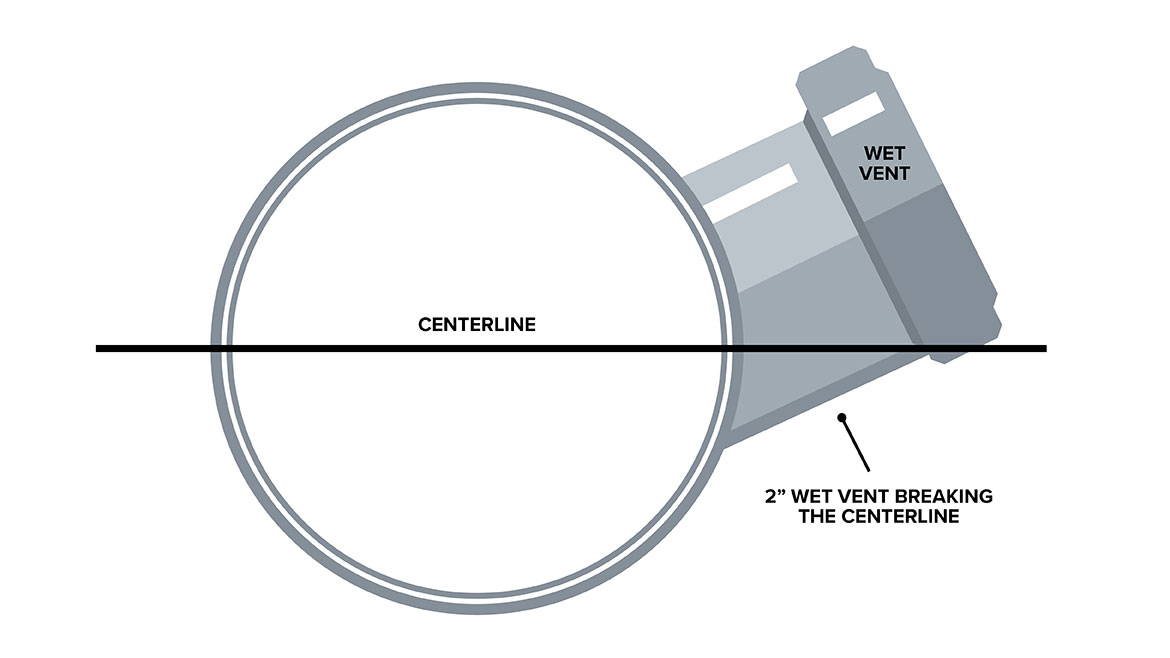

If we calculate the drainage sizing for a shower at 3-DFU (uses 5.7- to 12.3 gpm), we can still utilize a 2-inch trap and drain line. The 2 x 1.5-inch wye needs its branch to be rolled on an angle (see illustration) so that free airflow can be maintained for the wet vent.

How far can we run our 1.5-inch dry vent serving this bathroom group? Totaling up our DFU load: 1.28-GPF toilet = 3-DFU. The shower = 3-DFU. Lavatory = 1-DFU for a total of 7-DFU. IPC Table 906.1 indicates we must stay within 150 feet developed length. 906.3 states the developed length is measured from the farthest connection to the drainage system (you could argue that is from the 2 x 1.5-inch wye or starting where the dry vent begins at the 1.5-inch sanitary tee serving the lavatory sink to where it either joins a vent stack or to its termination above the roof.

Take full advantage of the minimum standards as set forth in our plumbing codes books in order to carefully redesign and install fully code-compliant DWV rather than blindly following the often outdated templates utilized by architects. You can successfully capture more jobs than your competitors by developing a thorough knowledge of DWV code-compliant installations. Wet venting codes really don’t differ greatly between the various code bodies. If you don’t mind investing a few extra dollars, get commentary editions of other codes as well because others, like NSPC (National Standard Plumbing Code), have far more detailed illustrations and if you’re like me, visual learning is understood and retained more easily. For example: NSPC Figures 12.2.1 – A and B illustrate quite graphically how positive and negative pressure forces affect the 2-inch trap seal.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!