Renewable Heating Design | John Siegenthaler

When one heat pump isn’t enough — part two

Simultaneous heating and cooling with multiple heat pumps.

Image Source: hirun / iStock / Getty Images Plus

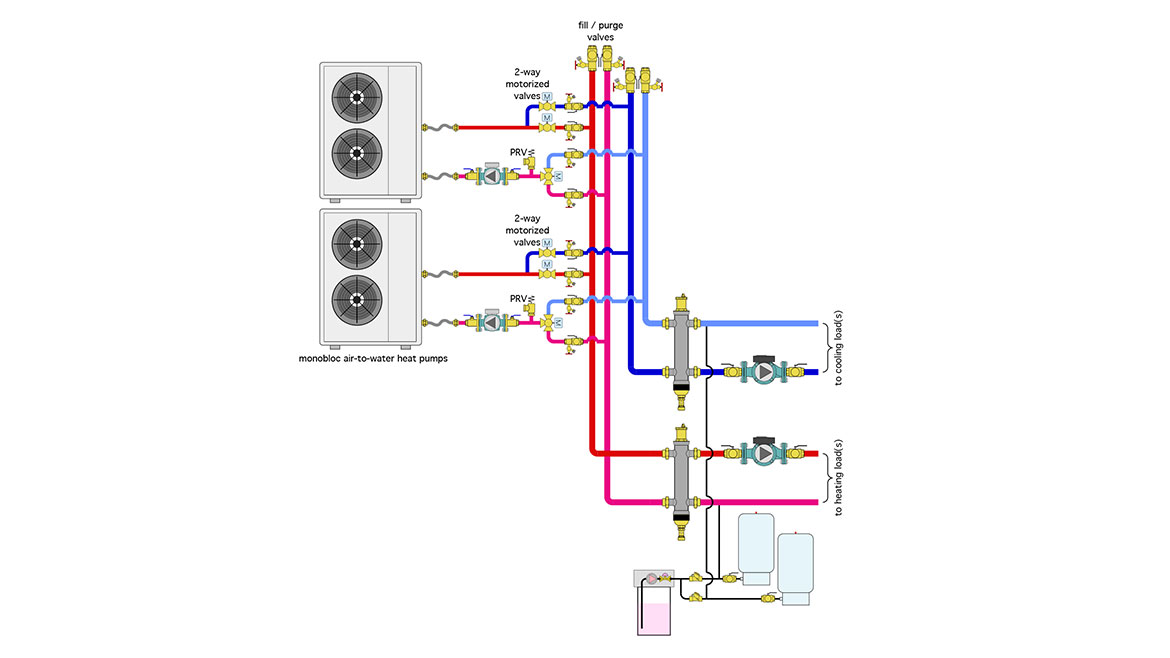

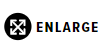

In last month’s Heating with Renewable Energy column, we discussed piping options for multiple air-to-water heat pumps. The simplest approach — a 2-pipe header system — allows for staging and modulation of each heat pump, but it doesn’t allow some heat pumps to supply heating while others supply cooling. When simultaneous heating and cooling is required a 4-pipe header system with motorized valves allows any heat pump in the “plant” to be called into heating or cooling mode operation. The system in Figure 1 shows such a system.

FIGURE 1

Figure 1. Image courtesy of John Siegenthaler

Read last month’s column to review the details in this piping configuration.

Adding Capabilities

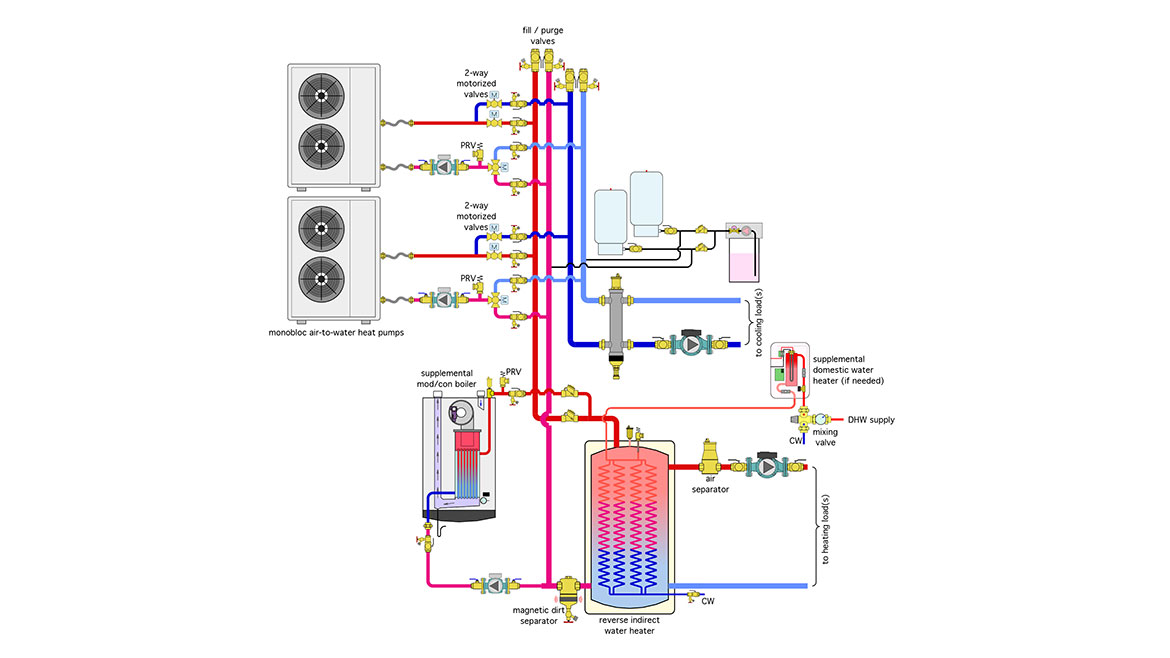

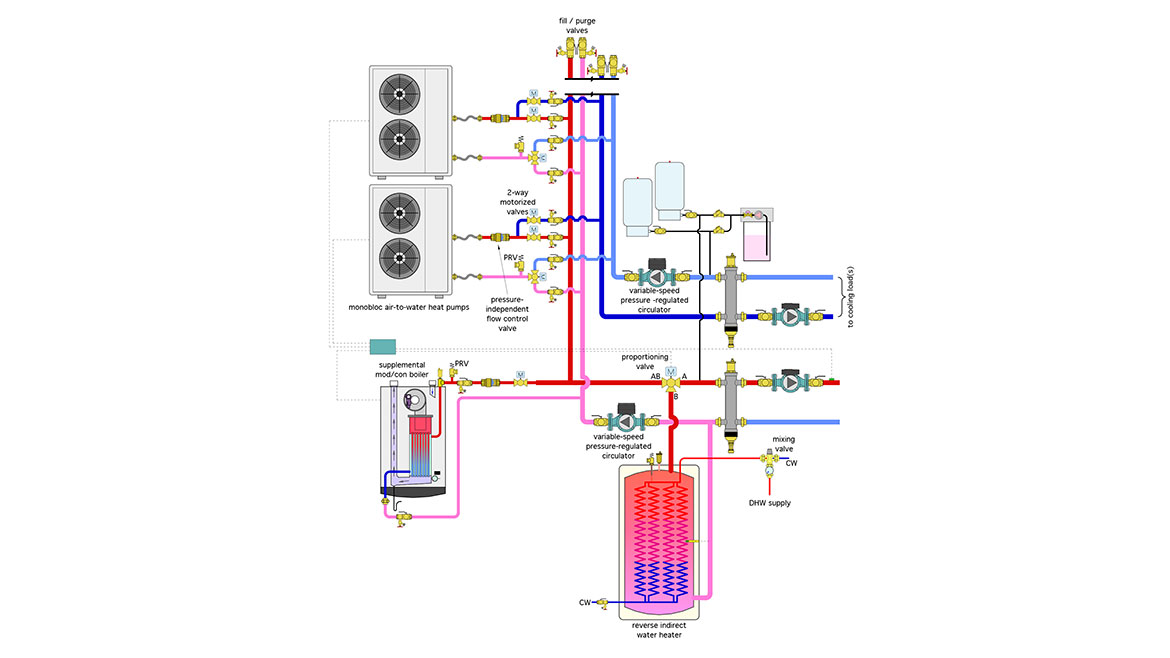

Many buildings that require multiple heat pumps for space heating and cooling also have a domestic water heating load. It usually makes sense to use the heat pumps to heat (or preheat) domestic water. Figure 2 shows how a reverse indirect water heater tank can be used for this function. This tank, connected as shown, also provides hydraulic separation of the circulators in the heating portion of the system, and eliminates one of the hydraulic separators shown in Figure 1.

FIGURE 2

Figure 2. Image courtesy of John Siegenthaler

Figure 2 also includes a boiler that can provide supplemental heat input for either space heating or domestic water heating.

Only When Necessary

A supplemental domestic water heater is also shown in Figure 2. It could be a tankless unit operating on natural gas or electricity. It could also be a tank-style heater. Its purpose is to boost the temperature of domestic water leaving the indirect tank — when necessary. This supplemental heater may or may not be necessary based on the temperature maintained within the reverse indirect tank.

If the staging/modulation controller operating the heat pumps and supplemental boiler is programmed to maintain the tank temperature based on outdoor reset control, there are likely to be times when the domestic water leaving the tank will not be hot enough to go directly to the hot water fixtures. This is especially true if the space heating distribution system supplies low-temperature heat emitters such as radiant floor panels. In this scenario, some type of supplemental heater is needed to boost the preheated water leaving the tank up to the desired delivery temperature.

If the controller operating the heat pumps and boiler maintains a setpoint temperature in the tank that’s 5° - 10° F higher than the desired DHW delivery temperature, the supplemental domestic water heater is probably not needed.

In situations where the DHW energy required during the heating season is a small percentage of the total (space heating + DHW) energy requirement, it’s likely that overall system efficiency will be improved by controlling the tank temperature based on outdoor reset. This is especially true if the DHW delivery temperature is high, and the space heating distribution system can operate at low supply water temperatures.

Another variant

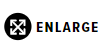

It’s also possible to configure a 4-pipe system with two variable-speed pressure-regulated circulators that provide all flow through the heat pumps and boiler(s) as shown in Figure 3.

FIGURE 3

Figure 3. Image courtesy of John Siegenthaler

Each variable-speed pressure-regulated circulator would be set for constant differential pressure mode and at the differential pressure required to achieve design flow rate through all connected heat pumps plus the supplemental boiler. The circulator will automatically reduce its speed as heat pumps or the boiler turns off.

Each heat source subgroup also includes a pressure-independent balancing valve (PIBV) that maintains a preset flow rate through its associated heat source whenever it is operating.

The variable speed circulators must be turned on when any of the connected heat pumps or the boiler are called to operate. When a heat pump is called to operate it will not turn on its refrigeration system until it verifies that an adequate and stable flow rate is established.

The connection points for the expansion tanks have also changed to put them close (from a ∆P perspective) to the circulator inlets.

This approach using variable-speed pressure-regulated circulators becomes increasingly more cost-effective as the number of connected heat pumps and boilers increases. It eliminates individual circulators on each branch as well as the isolation flanges and wiring needed for those circulators.

Separating DHW Production

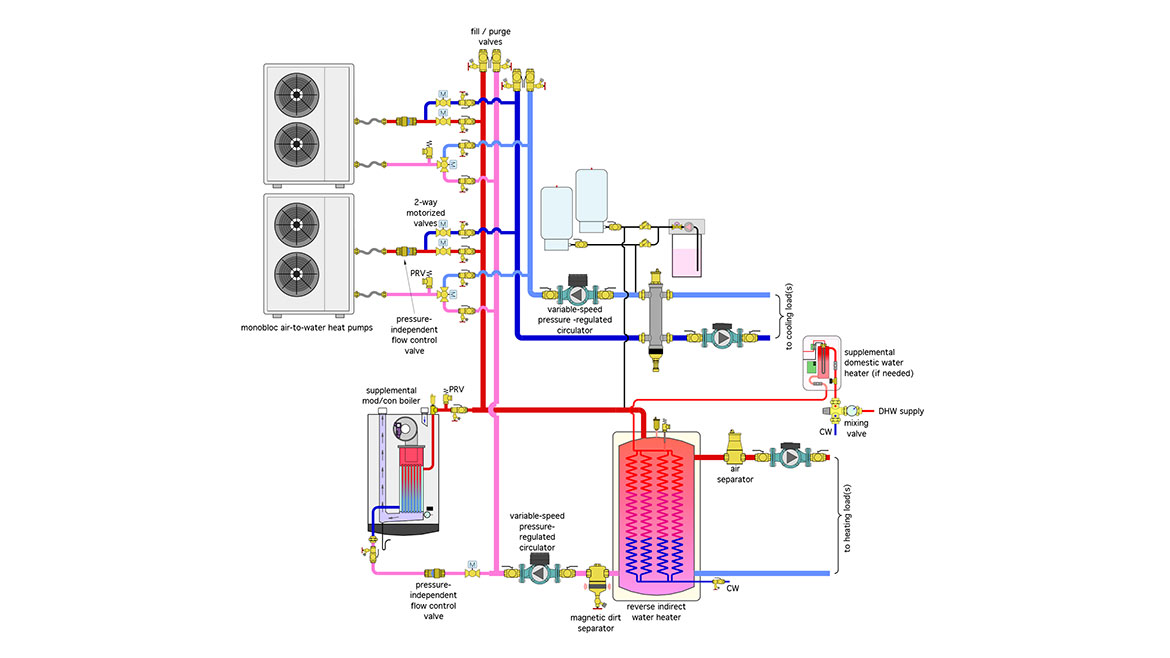

Figure 4 shows yet another variation on the 4-pipe system.

FIGURE 4

Figure 4. Image courtesy of John Siegenthaler

This system treats the indirect water heater as a separate entity rather than as a preheater / hydraulic separating device. It assumes that the system controls can detect a call for domestic water heating, and operate the heat pumps (and possibly the boiler) to produce a higher water temperature than might be required based on outdoor reset control for space heating.

It uses a proportioning 3-way valve controlled by a 0-10VDC or 4-20 ma signal to determine the amount of heated fluid from the heat sources that passes into the hydraulic separator versus the indirect water heater. The valve is controlled based on the measured supply temperature to the space heating system. The amount of hot fluid it allows into the hydraulic separator is based on maintaining the target supply temperature to the space heating load. All remaining flow from the heat sources passes through the indirect water heater.

When there is no call for domestic water heating all flow passes from the AB inlet port to outlet port A.

When the domestic water heating mode is active there can usually be some simultaneous heat input to space heating (if needed). If very high DHW loads are possible, the controller could direct all flow from the heat sources to the indirect water heater, (e.g., from port AB to port B), and thus treat DHW production as the priority load.

The Brains

Several suppliers of air-to-water heat pumps now offer controllers that can stage and modulate up to 4 heat pumps. Some of those controllers can also be “daisy chained” to accommodate more than 4 heat pumps.

For 4-pipe systems, where each heat pump can be called for either heating or cooling, the control logic must set either heating or cooling as the priority load. When only one mode is calling for energy, all heat pumps are available as needed to achieve and maintain the target supply temperature for that mode. When both modes are needed simultaneously, one or more heat pumps are staged in the priority mode until the target supply temperature is reached and maintained. At that point, any inactive heat pumps in the “plant” can be brought online to create a supply temperature for the other mode that’s as close to the target supply temperature as possible.

A basic BAS platform programmed with the necessary priorities to handle design load heating, design load cooling, and every partial load condition in between, is one possibility. As the market for multiple air-to-water heat pump systems expands, expect new controller offerings that allow contractors to configure multiple heat pump systems without the overhead of a BAS platform.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!