February Feature

7 observations on California’s — and the nation’s — ongoing move to electrification through heat pumps

The ultimate impact of California’s drive to replace gas water heaters with electric heat pumps will inevitably vary by state over the next decade. But will home and business owners — and the electric grid — be ready? Shouldn’t regulators — and professionals — pause to consider a more practical “hybrid” solution?

Image Source: Pavel Muravev / iStock / Getty Images Plus

Other than the shortage of skilled labor on job sites, there is no more consequential trend in the construction industry today than the move to electrification. This includes, of course, the recent rapid rise of electric heat pump technology for space heating and domestic hot water.

While the trend cannot yet be characterized as a genuinely national movement, its epicenter is the nation’s largest state, California, with a population of 40 million and an estimated gas-fired residential water heater count of roughly 10 million units. State environmental officials want to convert every one of those water heaters into electric heat pumps over the next decade as they come due for replacement.

What exactly does this “electrification” movement in the bellwether state of California portend for the rest of the country, particularly plumbers and HVAC techs who install and service water heaters? Decarbonization is a reality that will impact everyone over time.

For now, however, plumbing contractors find themselves in two large camps…

1. Two different worlds

If you are a contractor in a state with similar air-quality regulations as California — for example, Colorado, Utah, and a few others — you will likely need some type of electrical technology to comply with regulations. Your state may not be on the same timetable as California for ultra-low NOx emission requirements. But within the next five years, similar regulations are going to impact the homes or buildings your business works in.

That means we should all thoughtfully explore heat pump technologies for residential and commercial domestic hot water systems. The same thinking applies to specifying engineers.

It should be noted that California home builders are already making the transition to heat pumps, even though they are not mandated to do so until 2026. And it's not just a California thing: It's the whole West Coast. As those rules get adopted, more regions will follow; most notably, the Northeast. Your major population centers nationwide, including Chicago in the Midwest, are actively trying to move towards decarbonization in both residential and commercial construction.

Image courtesy of Noritz

On the other hand, if you work in a state not headed in the same direction as California, you probably are gratefully ignoring all talk about electrification mandates. Nobody has a crystal ball, of course: Mandates are inevitably driven by the whims of state legislatures and local governments, many of which are waiting to see what happens with the California rulings. If they start to get implemented, and there are no serious legal challenges, I expect other states will begin following California’s lead soon.

As for federal rulemaking related to the National Appliance Energy Conservation Act (NAECA), I don't expect a national rule mandating the elimination of gas. But Washington is going to push for a national transition to higher-efficiency equipment. We see this already in the Department of Energy’s new rules on storage-tank and tankless water heaters.

If you’re a contractor who installs nothing but non-condensing boilers or water heaters today, you might begin educating yourself on higher-efficiency gas equipment. Electrification may not be rocking your world right now, but higher-efficiency gas equipment is definitely in your future.

2. Banning gas? Not exactly

“Natural gas bans” is the short-hand phrase for what is happening in California and elsewhere in the United States. But California regulators would insist that’s not what they are up to — not directly, anyway.

The California Air Resources Board (CARB), the South Coast Air Quality Management District (AQMD), and the Bay Area Air Quality Management District (BAAQMD) have combined to set a new standard for NOx (nitrogen oxide, NO, and nitrogen dioxide, NO2) emissions, revising it sharply downward to zero parts per million (ppm). Effectively, they are banning all combustion with natural gas and liquified petroleum gas. Even pure hydrogen will emit one to three parts per million on initial firing, so it won’t work either.

Currently, the regulation is under 20 ppm and most gas-fired equipment is at 14 ppm. So, these entities are saying to manufacturers, if you're going to sell equipment that must be tested and approved for sale in California, you must adopt the zero ppm NOx requirement by the effective date.

Understand: The jurisdictions of those two air quality districts span 500 miles, north to south, from Napa Valley north of San Francisco all the way down to San Diego—a geography that contains roughly two-thirds of California's population.

The zero ppm requirement becomes effective in 2026 for all new residential construction and in 2029 for appliance replacement in existing homes. Regulators will not require the owners of those 10 million gas water heaters to rip out this equipment to replace it with electric heat pumps on Day 1, but to make the changeout gradually over time, as California did with low-flush toilets years ago.

Contractors eventually won’t be able to purchase gas-fired equipment from their favorite local supply houses. Some installers will probably bootleg them in from adjacent states, but the vast majority of Californians will need to transition to electric.

Meanwhile, industry manufacturers are not going to turn their backs on the largest market in the country. It’s just like the auto industry: Each state has its own requirements, but all cars comply with California environmental regulations. The same will go for water heaters: We will build our products for California and for other large states like Texas and Florida, and everyone—including manufacturers—will need to adjust to that reality as best they can.

3. Electrification = Electric Heat Pump

When I say “the transition to electric,” I mean electric heat pump equipment, including water heaters. As noted above, the new federal rules related to NAECA will mandate higher efficiencies for all appliances, including water heaters. That will mean the eventual elimination of all conventional electric-resistance, storage-tank water heaters for residential applications. All residential electric water heaters will transition over to heat pumps on or after May 6, 2029 (with some exceptions where you cannot use a heat pump).

This phase-out, which will be finalized before the end of 2024, is pretty much a sure thing. Depending on the change in the White House, all a newly elected administration can do is delay the implementation of the mandate.

I don’t expect any serious challenges from water heater manufacturers for the reasons I have already mentioned and because of the consumer-friendly benefits of heat pump water heaters:

- Energy efficiency: Heat pump water heaters are highly energy-efficient, as they transfer heat rather than generate it directly;

- Lower fuel bills: This increased efficiency translates to lower energy bills and reduced environmental impact; and

- Adaptable to virtually every region: These systems can operate in various climates, making them suitable for diverse regions.

Most households already equipped with a standard electric resistance water heater should benefit from switching to a heat pump, due in large part to the big rebates and lower operating costs.

4. Financial shock for consumers?

Manufacturer compliance is not a hard thing. We can develop a compliant product within 18 months. Industry manufacturers are working on this technology right now. Image courtesy of Noritz

Of course, the most painful switch will be for homeowners moving from a gas-fired water heater to an electric heat pump. As I travel the country and talk to consumers and industry professionals, I often hear and see their excitement over the green buzzwords surrounding decarbonization and electrification.

Unfortunately, consumers with gas equipment do not yet grasp the likely financial impact of that transition. It will be significant.

In California, gas is three times cheaper than electricity to generate the same amount of energy. Most gas states enjoy that same 3X or 4X ratio using gas. If you have a house like mine in which everything is gas — gas furnace, water heater, dryer, range cooktop — making the transition to electric will drive your monthly energy costs up significantly.

For example, for residential gas boiler replacements in Massachusetts, huge rebates are available for heat pump technology: up to $10,000 per home. But when the homeowner learns the price tag for a five-ton heat pump and a backup electric boiler is between $30,000 and $50,000, they’re stunned, usually reacting: “OK, just put in another gas boiler,” which costs only a small fraction of the electric decarb solution.

Most of the difference between these options is new infrastructure for the electrical equipment: maybe $10,000 for a bigger power line from the street to the home and another $3,000 to $5,000 to upgrade the breaker box. The average household simply isn’t ready for those conversion costs.

5. Grid investment: A huge question mark

Grid capability around the country is another key question, of course. I would say the electric infrastructure will be ready in California, but that’s because the state has been working toward the no-emissions mandate for many years. Title 24, also known as the California Building Standards Code, which sought to cut energy consumption, was introduced nearly a half-century ago in 1978. A decade later, it applied to all occupancies in the state.

More recently, the state has required solar capability in new homes, followed by a mandate for battery storage to offset grid strain during peak-load times. The upshot: While California communities are adding houses, the state is not increasing investment in the grid infrastructure. Instead, it puts the responsibility for energy storage on the homeowner. You fill up your battery in off-peak hours each day to handle the peak load and spare the utility.

But I don’t see the same level of investment or policy commitment in other states. For them to say, “We want to do what California is doing” becomes very dangerous for end users of hot water. As contractors and especially specifying engineers doing commercial work try to comply with the DOE’s rules, they will be hard-pressed to get enough power to a home or to a building for whatever equipment they specify and install.

Why do I say that? Even upgrading a transformer for a block of homes in a suburban neighborhood likely costs upwards of $500,000. My take: Most utilities lack the appetite to raise their rates to cover such investments. And I don’t see government mandates forcing the issue.

But I should reassure any contractor reading this article that the water heater product required to comply with the new zero-emissions mandates will be readily available throughout the country whenever the time comes. Manufacturer compliance is not a hard thing. We can develop a compliant product within 18 months. Industry manufacturers are working on this technology right now.

But that doesn’t mean homes, businesses, and factories will have sufficient power to run it.

6. Homeowners need help

So how should a contractor prepare for these dramatic changes in the way we heat water for domestic use? I would strongly recommend that plumbing and HVAC contractors need to start spreading the word now. Tell your customers with gas-fired equipment:

“You know these rules are coming. This is how they will impact your home. Maybe we should consider replacing your equipment, like-for-like, right now while we legally can. In two years, you will have to go to an electric solution, which may lessen the comfort you and your family currently enjoy with a gas-fired water heater.”

In California, we began transitioning from tank water heaters to tankless 25 years ago. There was a significant efficiency jump, but also a significant jump in comfort. People had tankless installed initially because of the cost savings, but then they came to love the superior level of comfort. They discovered they could take 50-minute showers or 10 showers back to back if they wanted without running out of hot water.

Heat pump technology is efficient, but you will sacrifice comfort. Put in that 65-gallon, 80-gallon, or 120-gallon tank, and you will get only X amount of hot water out of it. Then you might need to wait up to eight hours for the tank to recover.

Basically, in terms of comfort, the consumer who converts will regress to worse than a standard gas-fired tank heater.

7. All-electric mandates and gas bans are not the answer

The basic reality for our country today is that not every home or business owner can afford to convert to 100 percent electric. Going entirely electric may be more widely practical in another 10 to 15 years, but not today. In my opinion, the better way to maximize both energy savings and acceptance by the general public would be to give people a choice and let them install a hybrid dual-fuel solution that combines electric with gas equipment.

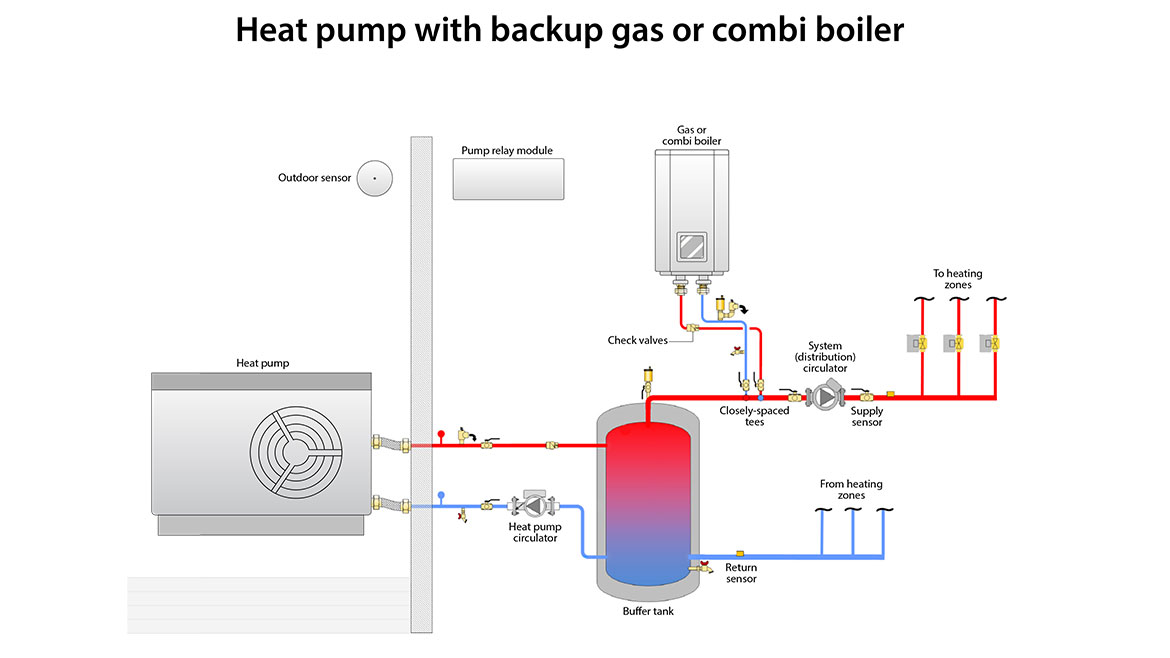

For example, install an electric heat pump to handle 80 percent of the load. But instead of an electric resistance boiler as a secondary source, go with a condensing gas boiler backup to supplement the heat pump during peak demand periods or when the grid is strained. The home or business owner will still save a substantial amount of energy and cost, as will the general community. But this dual fuel option would not require the large, short-term, public and private outlays for infrastructure changes that an all-electric setup inevitably requires.

Also, the all-electric mandate forces us to become dependent on a single utility type. It’s a big risk that’s not being adequately discussed, but that’s the path we’re on right now.

I want to close this article by repeating what I wrote earlier: Contractors and their residential and commercial customers should not panic that the right product will not be there to comply with the new regulations; or that they will lack the right training to install and service whatever technology is mandated. Every water heater manufacturer possesses sufficient engineering skills and production resources, so building the right equipment in a timely fashion is seldom a problem.

There are bigger concerns: Are we manufacturers truly providing the right equipment for our customers? How can we be as environmentally friendly as possible while generating maximum technology adaptation?

In my view, the hybrid dual-fuel option is the best way to achieve those goals.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!