Steam, the Original ‘Bad Boy’

Don’t approach steam like a hot water system.

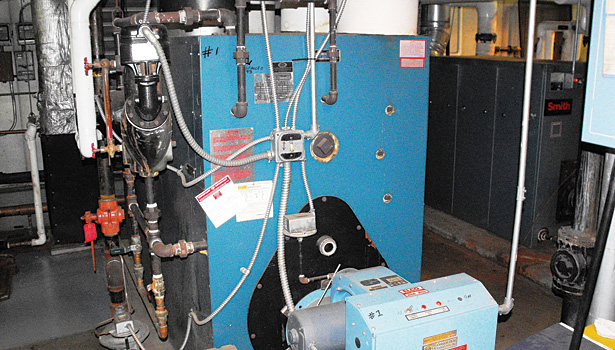

A cast-iron steam boiler.

Photo credit: Ray Wohlfarth

A high-efficiency steam boiler.

Photo credit: Ray Wohlfarth

A steam trap, which should be checked yearly.

Photo credit: Ray Wohlfarth

Steam systems have the reputation of being the “bad boy” of the industry and I believe it may be unfounded. Many contractors will suggest replacing the steam system with a new system but it may be fiscally unrealistic to do so. In many instances, conversion of the system from steam could require replacement of the entire system, including piping, boilers and radiators. If the client cannot afford replacement, the next option would be to optimize the existing system.

One of the common misconceptions with steam systems is to approach it as you would a hydronic system. If you do, the system will never operate correctly. Steam systems have to be serviced holistically as what happens in one room can and will affect other parts of the system.

My first exposure to a steam system was when my new spouse and I purchased our first house that had an improperly installed one-pipe steam system. During the first night in the house, I was awakened by a “psst.” I awoke quickly, thinking it was my spouse feeling adventurous. Alas, it was my large cast-iron radiator bleeding air. This continued all night, every night, until I learned how to properly operate the boiler and correct the near-boiler piping.

Thank-you, Dan Holohan, for your book! In an attempt to understand my system, I became fascinated with steam. I had grown up with a forced-air system that was incredibly noisy when it ran. If you were watching TV at the time the furnace started, you would be forced to turn up the volume.

I think a steam system can be a very versatile heating system. My kids loved to place their winter clothes on the radiators after coming in from playing in the snow. Their gloves and boots would be warm and dry for their return trip outside after a quick lunch. I personally enjoyed the feeling of a towel warmed by the radiator upon leaving the shower. I also discovered that wet leather shoes placed atop the radiator would magically be transformed into elf shoes, complete with curled-up toes.

People in the industry assume that steam systems are inefficient. I disagree. “What about latent heat?” they ask. The industry accepts that air-conditioning systems require a change of state for them to work but not boilers. A Btu is the approximate amount of energy generated by the burning of a wooden match stick. It takes about 1 Btu to raise 1 lb. of water 1°. That is until the water temperature reaches 212° F. It will then take an additional 970 Btu to convert that 1 lb. of water at 212° to steam vapor at 212°.

That is called latent heat. While the amount of Btu required for water to change its state from a liquid to a gas is excessive, it is not wasted. The Btu generated in the boiler room will be dispatched to the building and given up to the radiators. It is like money going from your savings account to your checking account and then returning to your savings account.

Another advantage with steam is that it will whip through even the tallest of buildings at speeds up to 60 miles per hour without the use of fans, compressors or pumps.

Steam System Tips

- Steam traps. According to SchoolFacility.com, steam traps have a life expectancy of three seasons. I would wager that many of the buildings where you service the boiler have traps much older than that. Many may be as old as the building. Traps should be checked yearly and replacements budgeted for every few years.

-

Pipe insulation. Steam systems require pipe insulation for efficient and quiet operation. A bare pipe will lose five times as much heat as an insulated pipe. In addition to energy savings, the system will work much better if the steam will not condense in the piping before it reaches the radiators. According to the 2009 International Energy Code, steam pipe of 1 1/2 in. and smaller should have 1 1/2 in. insulation. Steam pipe larger than 1 1/2 in. should have 3 in. insulation (Table 503.2.8).

The condensate pipe also should be insulated as this will limit the damage that can be done from carbonic acid. Carbonic acid is formed when steam condenses and carbon dioxide is released and mixes with the condensate to form the acid. -

Controls. Controlling multiple steam boilers is sometimes a bit tricky. I have found that all the boilers should be started at the same time and then, once steam pressure is generated, the boilers can be staged off. When only one boiler is started in a bank of multiple steam boilers, the lone boiler will run continuously and will never build pressure. Think of it like an airplane. An airplane will require the most energy when taking off and once the plane is at its desired elevation, the pilot can pull back on the throttle and allow the airplane to coast somewhat.

Night setback is sometimes a challenge as well due to the slow recovery of steam systems. They are slow to heat and slow to cool. A church in my area found it would have to go from night setback to day setting at 4 a.m. so the church would be warm by the 8 a.m. service in cold weather. They were able to drop back to the night setback temperature at the start of the last service of the day and the building would stay comfortable until the service was done.

Each building will react differently to the night setback temperature. It will require a trial-and-error method of finding what works best for each building. - Steam pressure. Most old systems were designed to operate on 2 lb. of steam pressure or less. If the pressure control is set higher, it will waste money and could cause reduced system life. For example, a steam system set at 7 lb. of pressure will have a steam temperature of 232°. Some steam traps are designed to open once the steam temperature drops 20°. At that lower temperature, 212° F, the condensate will flash back to steam, impeding the flow of condensate. If you see steam coming from the condensate or boiler feed tank, it could indicate leaking traps or excessive steam pressure.

Helpful Links:

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!