Air-to-water heat pumps and boilers

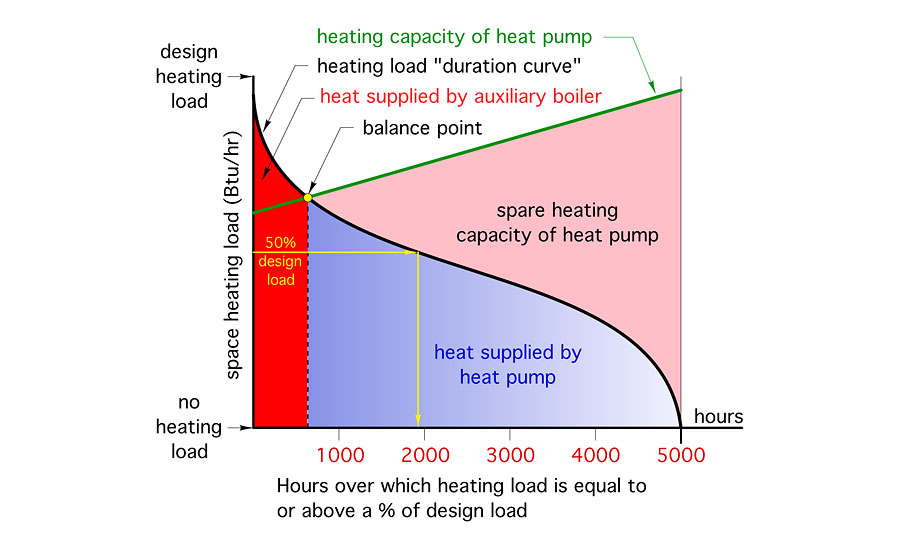

Figure 2.

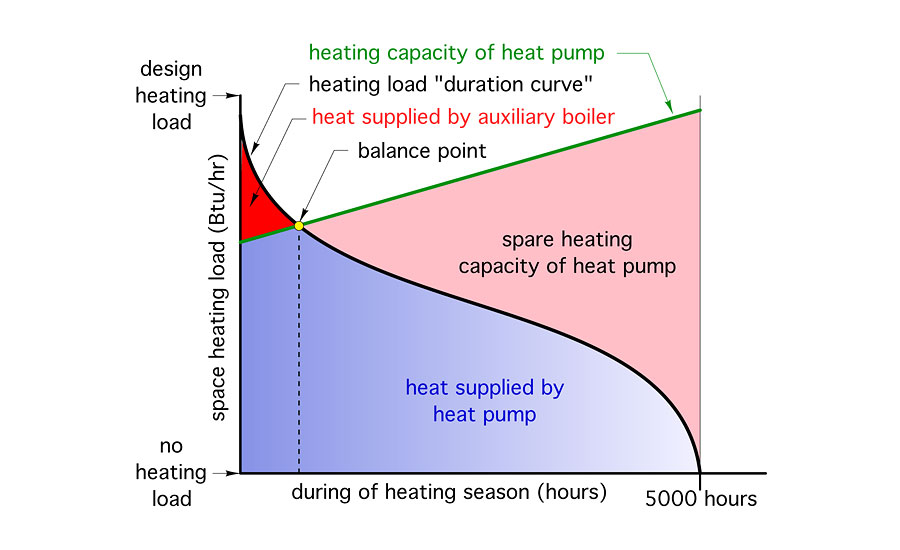

Figure 3.

Figure 1. An air-to-water heat pump. Photo credit: SpacePak

Air-to-water heat pumps represent a growing alternative to geothermal heat pumps in many parts of North America. The latest refrigeration technology allows these units to maintain heating capacity down to 0° F (outdoor temperatures) while also delivering 140° water to the load.

An air-to-water heat pump, such as in Figure 1, gathers low-temperature heat by refrigerating outdoor air during the heating season. The low-grade heat is “upgraded” to higher-temperature heat using a refrigeration cycle. This heat is transferred to a stream of water, or water/antifreeze mixture, where it’s ready for distribution using a low-temperature hydronic distribution system.

In areas where low-priced natural gas is not available, the cost of heat delivered by an AWHP, on a dollar per MMBtu delivered basis, is often significantly lower than that delivered by propane or fuel oil. Since most AWHPs operate on electricity, they can be combined with on-site electrical generation such as that provided by solar photovoltaic systems.

This option is especially attractive where net metering is available. Kilowatt•hours of electrical energy can be “banked” back to the utility grid from spring through fall, and then recalled to operate the heat pump during the doldrums of winter. With net metering, no financial penalty is associated with this. It’s as if the utility grid is an infinitely sized, free-storage battery, operating at 100% efficiency.

Another compelling reason to use an AWHP is it can provide cooling during warm weather. Just like most geothermal and air-to-air heat pumps, AWHPs contain refrigerant-reversing valves that allow them to serve as chillers. As such, they can produce a steady stream of chilled water in the temperature range of 45° to 60° for use in hydronic cooling systems.

Keys to great performance

The heating performance of an AWHP depends on outdoor temperature as well as the load water temperature. The warmer it is outside and the lower the leaving load water temperature (e.g., the temperature of the water leaving the heat pump condenser), the higher the heating capacity and coefficient of performance of most AWHPs.

Obviously, there’s not much anyone can do to alter outdoor air temperature. However, designers do have options when it comes to determining the load water temperature required of the heat pump. The goal is simple: Design the heating distribution system for the lowest possible supply water temperature.

My suggestion is to design all hydronic distribution systems, especially those that will be (or might be) connected to heat pumps, so that they will deliver full design-load output with a supply water temperature not exceeding 120°. Systems using low-temperature floor, wall and ceiling radiant panels, as well as generously sized panel radiators, can all meet this criteria. In some cases, even properly sized “low-temperature” fin-tube baseboard can operate with supply water temperatures in this range.

In very cold climates where several consecutive days of sub-zero weather can occur, there are times when the heating capacity of an AWHP will likely fall short of the heating load. Lack of sufficient capacity might occur when the outdoor temperatures are at, or close to, their minimums. It also might occur during periods of high demand, such as during recovery from temperature setbacks.

At these times, a supplemental heat source can provide the extra heat needed. If propane is available and cost-competitive against straight electric resistance heating on a dollar per MMBtu delivered basis, a modern propane-fueled mod/con boiler is a good choice as the supplemental heat source. Having such a boiler also provides a backup heat source if the heat pump is not operational. The relatively low electrical wattage required by such a boiler allows it to operate using modestly sized standby generators during power outages.

There are two ways to use the auxiliary boiler to supplement a heat pump. The first uses either the AWHP or the boiler as the system’s sole heat source, depending on outdoor temperature.

The second allows the possibility of using both heat sources simultaneously.

Which approach is best depends on the relative cost of energy supplied by the heat pump vs. the fuel used by the boiler. It also depends on how low the outdoor temperature can drop before the heat pump should not be operated. Some modern low-ambient heat pumps can operate at outdoor temperatures below 0°, albeit at reduced heating output and low COPs.

Either/or

The first method uses the heat pump to supply the heating load until the outdoor temperature drops to the point where the heat output from the heat pump is insufficient to meet the load. The heat pump is then turned off and the auxiliary boiler is turned on. The concept is illustrated in Figure 2.

The heating load duration curve represents the severity of the heating load vs. the number of hours the load is equal to or above a given percentage of design load. For example, in Figure 2, the heating load is equal to or above 50% of design load about 1,900 hrs. per yr., as shown by the yellow lines. This graph assumes that an average heating season lasts 5,000 hrs. per yr., which is just under seven months.

The exact shape of the heating load duration curve varies from one climate location to another. However, the curve’s general shape will remain similar to that shown in Figure 2. This curve shows the number of hours of severely cold weather, when the heating load is perhaps 90% or more of design load, are very limited, compared to the hours where the heating load is a smaller percentage of design load.

The “balance point” is where the heat output from the heat pump equals the heating load. The red-shaded area to the left of the balance point represents the time during which the boiler is meeting the load. In Figure 2, this is approximately 600 hrs. per yr. The blue-shaded area represents the time when the heat pump supplies the heating load. In Figure 2 this is about 4,400 hrs. per yr. — all but the time the boiler is supplying the load.

The mathematical areas under the heating duration curve represent the total energy supplied. The red area represents the total energy supplied by the boiler and the blue area shows the total energy supplied by the heat pump. If energy supplied by the heat pump is less expensive than that supplied by the boiler, the goal is to minimize the red area as a percentage of the total area under the curve.

The extent to which this can be done depends on the heating capacity of the AWHP relative to the design load. It also depends on how the heating capacity of the heat pump falls off with decreasing outdoor temperature. Selecting a higher capacity AWHP, relative to the design load, will move the balance point to the left, decreasing the energy contribution of the boiler. However, it also will increase installed system cost. The more expensive the boiler’s fuel is compared to the heat supplied by the heat pump, on a dollar per MMBtu basis, the farther the balance point should be moved to the left. This minimizes the energy contribution of the more expensive boiler fuel.

The pink-shaded area shows where the heat pump’s heating capacity exceeds the load. This area implies that spare heating capacity is available from the AWHP much of the heating season. Good designers will use this available capacity for preheating, or perhaps even fully heating, domestic water.

Cooperating capacity

The second approach to combining an AWHP with a boiler keeps the heat pump in operation whenever there is a heating load and supplements its output, as necessary, using the boiler. This scenario is represented in Figure 3.

Notice how the blue-shaded area now spans the entire heating season. The red-shaded area is significantly smaller than in Figure 2, indicating that the boiler supplies a smaller percentage of the total space heating required over the season.

The feasibility of this approach depends on several factors. First, can the heat pump operate during the coldest outdoor air temperatures experienced at the site? In most areas of the United States, the answer is likely yes. In bitter-cold areas with outdoor temperatures dropping below -10°, the answer is likely no. The heat pump manufacturer should be consulted for information on the minimum acceptable outdoor temperature at which the unit should be operated.

Second, how does the cost of heat supplied by the heat pump, operating under low outdoor air temperatures, compare to that supplied by the boiler on a dollar per MMBtu basis? Remember, the COP of most AWHPs under very low outdoor temperatures will drop significantly. If the cost of energy supplied by the boiler is comparable to that supplied by the heat pump, there may not be any incentive to keep the heat pump operating under very low outdoor temperatures. Shut it off and save the operating hours for more favorable conditions.

Next month we’ll look at how to pipe up a combisystem that can supply space heating, space cooling and domestic water heating using the combined attributes of an AWHP and auxiliary mod/con boiler.

This article was originally titled “Dynamic duo” in the October 2015 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!