Home » troubleshooting

Articles Tagged with ''troubleshooting''

As 2021 draws to a close, we revisit the articles which caught the attention of our readers the most.

Read More

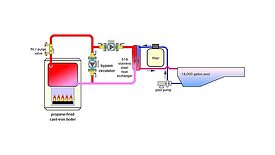

Dan Holohan: Marbles and ghosts

Visual thinking is key to understanding hydronic systems.

December 8, 2021

Heating Help

Dan Holohan: Does size matter?

Big or small, contractors do it all.

December 2, 2021

HEATING HELP

Dan Holohan: Who gets to work on steam?

Always read the instructions.

November 1, 2021

Heating Help

Dan Holohan: What's inside?

Approach troubleshooting by thinking like the system you’re working on.

September 2, 2021

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing