Geo shortfalls

The Glitch & The Fix, March 2017

Can you identify at least four design deficiencies or operation issues that are likely to develop if the system is installed as shown?

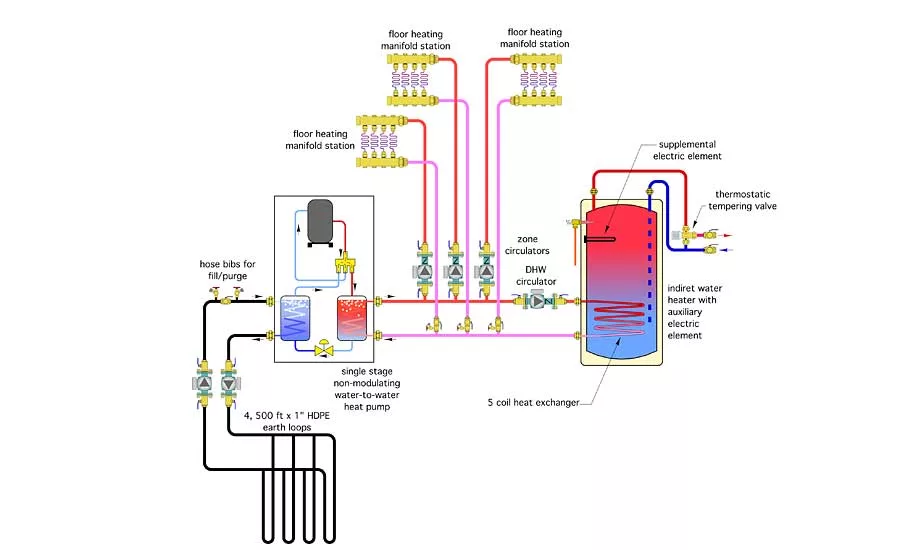

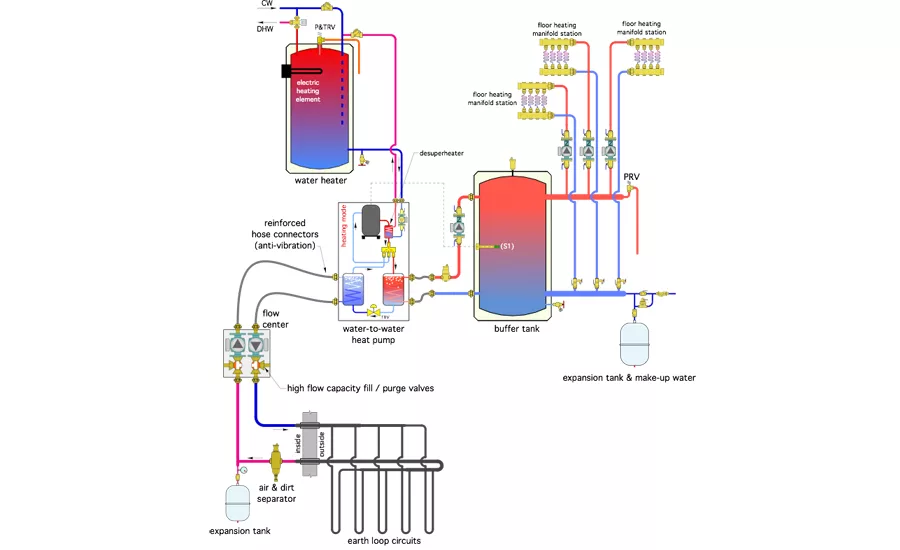

The Fix: I also recommend that the earth loop be equipped with a properly sized expansion tank as well as an air/dirt separator, as shown here in The Fix.

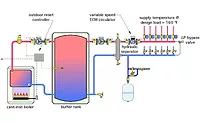

The Glitch

An installer is asked to provide a multi-zone floor heating system supplied from a single-stage non-modulating geothermal heat pump. The radiant floor panels will be low thermal mass. The system also needs to provide domestic water heating. The system he designs is shown above.

Assume that the amount of earth loop tubing is sufficient for the capacity of the heat pump. Can you identify at least four design deficiencies or operation issues that are likely to develop if the system is installed as shown?

The Fixes:

Any single stage non-modulating heat source coupled to a zoned distribution system is likely to experience short cycling. This is especially true if the floor heating installation is low-mass. When only one or two zones are operating, they cannot dissipate heat into the building as fast as heat is generated by the heat pump. The water temperature between the heat pump and operating zones will quickly increase, and the heat pump will turn off on an internal safety. It may or may not automatically restart depending on how its internal controls are configured. Even if it does restart automatically, the short cycling will be chronic.

The solution is to install a buffer tank between the heat pump and space heating loads, as shown below. This allows the rate of heat generation by the heat pump to be very different from the rate of heat dissipation by the load. This tank, in combination with the generously sized headers, provides good hydraulic separation between the zone circulators and the heat pump-to-buffer-tank circulator.

The coil heat exchangers in most North American indirect domestic water heaters simply don’t have enough surface area to dissipate the output of a 4- or 5-ton heat pump, while operating at the upper supply water temperature limit of the heat pump (typically 120-125° F). The coil won’t be able to dissipate heat into the tank as fast as heat is being generated by the heat pump. Again, short cycling will be the modus operandi.

There are several alternatives for providing domestic hot water. The simplest is to select a heat pump equipped with a desuperheater heat exchanger. Heat from the hot refrigerant leaving the compressor is transferred to domestic water and moved to a standard electric water heater tank whenever the heat pump is operating. The upper electric heating element in an electric DHW tank provides any supplemental heating. This option is shown in The Fix (above).

Then there’s the earth loop. Even though there’s sufficient tubing in the ground, getting it filled and properly purged through a set of hose bibs is going to be futile. It takes a substantial flow and differential pressure to simultaneously purge four parallel earth loops. Think nominal 2 hp pump rather than small submersible transfer pump. Adequate purging flow requires much higher flow capacity purging valves. A common solution is to use a geothermal “flow center” specifically matched to the earth loop. Several types of flow centers are available with high capacity fill/purge valves and circulator options to match the flow and head loss of the earth loop.

I also recommend that the earth loop be equipped with a properly sized expansion tank as well as an air/dirt separator, as shown in The Fix. These allow for less pressure variation in the loop as it changes temperature and facilitates cleaner, quieter flow.

Other issues with the system in The Glitch include:

-

Some purging valves are upside down.

-

There should be a purging valve on the return side of every load circuit.

-

The inlet of the zone circulators is very close to the header. There should be at least 12 pipe diameters (12D) of straight pipe on the inlet to any circulator.

-

There is no expansion tank or make up water hardware shown on the load side of the system.

-

There is no air separator in the load side of the system.

-

There’s no pressure relief valve in the load side of the system.

Check out Geo shortfalls in pdf form.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!