Hydronic vs. VRF - which, when and why?

Mechanical contractors, specifying engineers and building owners have many options when it comes to heating and cooling buildings.

ASHRAE headquarters in Atlanta. Photo credit: Xylem AWS

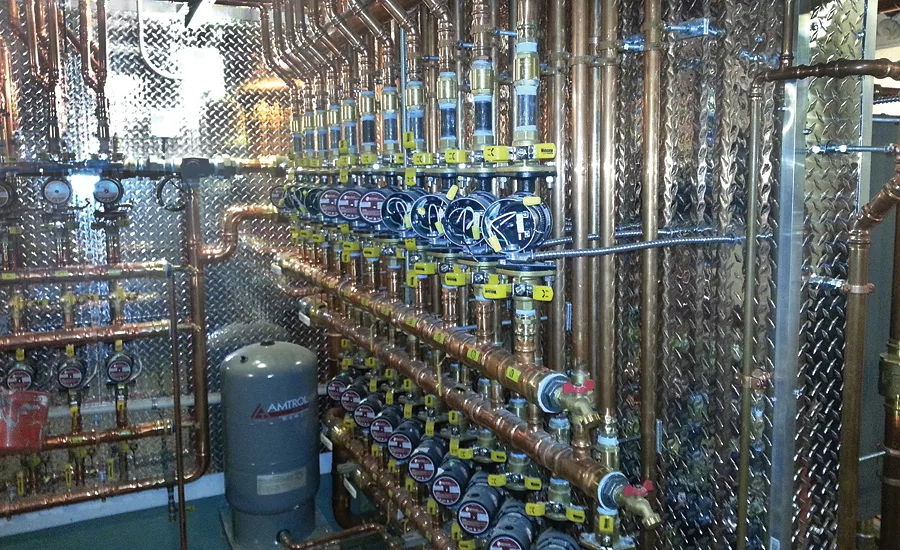

This system includes a Bell & Gossett Heat Exchanger. Photo credit: Xylem AWS

This hydronic system installed at the Newport Mansion in Rhode Island includes Bell & Gossett ecocirc XL circulator pumps. Photo credit: Xylem AWS

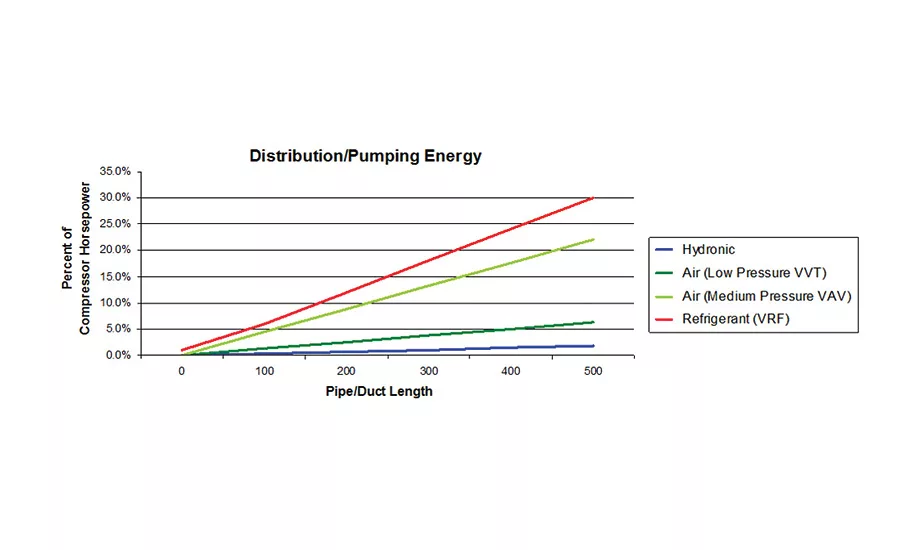

Distribution/Pumping Energy. This graph compares the efficiency of VRF and hydronic systems.

Mechanical contractors, specifying engineers and building owners have many options when it comes to heating and cooling buildings. Maintenance and life-cycle costs are important factors to consider when selecting which system to install, especially when seeking to control costs and improve the reliability and efficiency of an HVAC system.

An apples-to-apples comparison of hydronic systems and variable refrigerant flow (VRF) systems is beneficial in selecting the best system for a building. While VRF is attractive for its ductless technology and claims of superior energy efficiency, industry studies demonstrate how hydronic systems outperform VRF systems in terms of energy use.

Hydronic systems provide water-based heating and cooling through pipes, ductwork and other components such as pumps, drives, controls, heat exchangers and valves. VRF systems use refrigerant as their cooling/heating medium and are comprised of a compressor unit connected through refrigerant lines to multiple indoor cassette units that can be individually controlled.

A 2013 study by Oklahoma State University and Oak Ridge National Laboratory, which evaluated the performance of geothermal heat pumps (GHPs) versus VRF heating and cooling systems installed at the American Society of Heating Refrigeration and Air-conditioning Engineers (ASHRAE) International Head-quarters in Atlanta, found that GHPs use 44% less energy than VRFs on an annual basis.

Compared to hydronic systems, VRF systems are expensive in terms of first costs — in many cases, 5-20% higher because of their complex refrigerant management system and controls. VRF systems typically require a dedicated outdoor air system to meet ASHRAE 62 ventilation codes, which may add to first costs.

Along with higher first costs, VRF systems have a shorter life expectancy. Hydronic systems have been known to last 20 to 25 years while VRF systems could need replacing 10 to 15 years after installation. This is because the compressor in a VRF system must operate during both heating and cooling cycles, reducing its product life.

For those who specify HVAC systems for new construction and retrofits, it’s important to explore the operational performance and efficiency disparities between VRF and hydronic systems. Here are some of the key differences.

Energy sources

Hydronic heating and cooling systems are easily adaptable to a wide variety of current and future energy sources, from natural gas and propane to renewable energy sources like solar thermal collectors and biomass boilers. In contrast, VRF systems are solely powered by electricity.

Climate control

Extremely hot or cold air conditions can impact the performance of both hydronic and VRF systems, though hydronic systems are less affected by temperature changes. The efficiency of a VRF system is reduced as the ambient temperature goes up in the cooling mode and down in the heating mode. Additionally, a VRF system may require a supplementary heat source in cold climates, such as gas heat from a boiler, which may negate the energy efficiency of the system.

A VRF system can provide zoned comfort, recovering heat from one zone to use it in another. This is effective in buildings like hotels and schools, which run both heating and air conditioning at the same time. However, a VRF system does not have thermal energy storage capabilities.

Water-based hydronic systems, like a water-source heat pump system, can draw the heat or chill out of a room and carry that energy back to the system for later use, reducing energy consumption and costs.

Building scope

When specifying a system, it’s important to consider not just building size, but also the size of the HVAC system itself. Hydronic systems are better suited to handle buildings requiring 50-100 tons of cooling capacity or more. They also have the capacity to pump water efficiently and effectively over very long distances, such as across a sprawling campus or through high-rise office buildings.

A VRF system is generally limited to historic buildings or buildings fewer than three stories because the length of piping run must be limited in order to carry refrigerants and oil through the building in accordance with manufacturer guidelines. Long lengths of piping can jeopardize performance of the unit if oil or refrigerant accumulates in the piping or migrates back to the unit. A larger project could include multiple VRF systems, but that significantly increases costs.

Distribution/Pumping Energy. This graph compares the efficiency of VRF and hydronic systems.

Distribution/Pumping Energy. This graph compares the efficiency of VRF and hydronic systems.

Specialized technicians

VRF systems require specialized technicians for installation, adjustments and repairs compared with hydronic water systems designed with universal components that can be installed and serviced by any plumbing, heating and cooling service technician. This adds to life-cycle costs of the VRF system, as building owners will be dependent on specialized technicians for the life of the system.

Since VRF piping requires mechanical fittings, brazing and soldering on-site, the quality of installation depends on the installer’s level of expertise. Installers must be qualified to work with refrigerants under extremely high pressure and be knowledgeable about refrigerant piping locations under their state’s International Mechanical Code (IMC), as well as leak detection and ventilation requirements per ASHRAE Standard 15.

Refrigerant safety

In late 2016, the U.S. Environmental Protection Agency (EPA) updated existing requirements related to ozone-depleting substances, extending them to hydrofluorocarbons (HFCs) like R-410A, which is the current refrigerant choice in the HVACR industry.

The updates, which will take effect on Jan. 1, 2019, include:

-

More stringent requirements for repairing leaks in larger appliances;

-

New recordkeeping for the disposal of appliances containing 5 to 50 pounds of refrigerant;

-

New reporting requirements for chronically leaking equipment; and

-

Restricting the sale of HFC refrigerant to technicians certified under Sections 608 or 609 of the Clean Air Act.

It is possible for leaks to develop in both hydronic and VRF systems, but a leak in a VRF system is potentially hazardous. Refrigerant leaks cannot be detected by sight or smell, making them hard to find and difficult to repair. In spaces with minimal ventilation, refrigerant concentrations can potentially reach values that put people at risk of losing consciousness and even suffocation.

Under the EPA’s updated refrigerant management requirements, the leak rate must be calculated every time substitute refrigerant is added to equipment (unless the addition is made immediately following a retrofit, installation of a new unit or qualifies as a seasonal variance).

The final rule also includes the following provisions for owners and operators of refrigeration and air-conditioning systems:

-

Quarterly or annual leak inspections or continuous monitoring devices for refrigeration and air conditioning equipment that has exceeded the threshold leak rate;

-

Owners or operators must submit reports to the EPA if systems containing 50 or more pounds of refrigerant leak 125% or more of their full charge in one calendar year;

-

Sales restriction are extended to HFCs and other non-exempt substitutes, with the exception of small cans (2 pounds or less) of non-exempt substitutes for motor vehicle air conditioner servicing; and

-

Technicians are required to keep a record of refrigerant recovered during system disposal from systems with a 5- to 50-pound charge size.

The phasing out of refrigerants like R-410A over the next 10 years could have a costly impact on existing VRF installations as the entire system — including piping, outdoor units and fan coils — will need to be replaced.

Hydronic systems are the prevailing heating and cooling technology because they enable engineers, contractors and building owners to adapt to changing system demands. As we look ahead, they will continue to be the systems of choice because of their cost, performance and efficiency.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!