Home » troubleshooting

Articles Tagged with ''troubleshooting''

The Glitch & The Fix: Januar 2025

The Glitch & The Fix

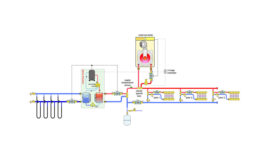

Installation nightmare — how many problems can you spot?

November 27, 2024

The Glitch & The Fix

One size doesn't fit all when it comes to piping sizes

October 29, 2024

The Glitch & The Fix

Concrete slab over radiant tubing — who takes the blame?

April 24, 2024

The Glitch & The Fix

Eliminating the temperature drop effect

Avoiding sequential temperature drops

January 3, 2024

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing